The Ultimate Guide to CNC Machining: A Comprehensive Overview

At JawsTec, we are experts in CNC machining, a manufacturing process that uses computer-controlled tools to create highly precise and intricate parts. In this ultimate guide to CNC machining, we will cover all aspects of the process, from its history and applications to the advantages and disadvantages, as well as some tips for selecting the right CNC machining services provider.

A Brief History of CNC Machining

CNC machining, or Computer Numerical Control machining, traces its roots to the 1940s, when the US Air Force developed a system to automate the production of complex airplane parts. The first CNC machine tool was developed by John T. Parsons and Frank L. Stulen in the late 1940s at the Parsons Corporation. The technology rapidly advanced in the following decades, and by the 1980s, it had become widely adopted in the manufacturing industry. The base creation for it is g-code behind now more advanced methods for developing a tool path and cutting the parts.

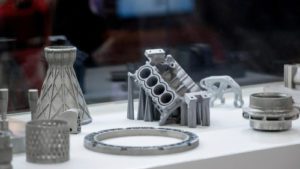

Today, CNC machining is used in a wide range of industries, including aerospace, automotive, medical, and electronics, to name a few. Machinists program the cnc system for cutting parts by cnc milling or cnc turning. Some machines even have edm capabilities built into them. Its precision and versatility make it a preferred manufacturing process for creating complex and customized parts with high accuracy. The machinery uses all sorts of different fixtures, tooling, drilling, milling, and clearing methods. Automation has gotten a lot better as well and now robotics are able to setup and run the cnc parts.

How CNC Machining Works

CNC machining uses computer software to control a cutting tool and remove material from a workpiece to create a finished product. The process involves three main stages: CAD design, CAM programming, and CNC machining.

In the CAD (Computer-Aided Design) stage, a digital model of the part is created using specialized software. This design is then converted into CAM (Computer-Aided Manufacturing) code, which instructs the CNC machine how to move its cutting tool to create the part. The code is then fed into the CNC machine, which uses its software to translate the code into precise movements of the cutting tool, removing material from the workpiece until the part is complete.

Advantages of CNC Machining, Lathe, Milling

CNC machining offers several advantages over traditional manufacturing processes, such as manual machining or injection molding. Some of the benefits include:

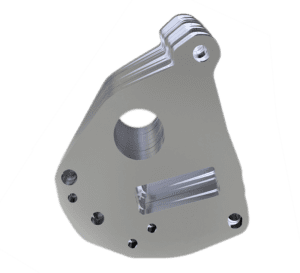

- High precision: CNC machines are capable of producing parts with tolerances as low as 0.0001 inches, ensuring a high level of accuracy and consistency.

- Versatility: CNC machines can produce a wide range of parts with varying complexity and material properties, from simple flat parts to complex geometries.

- Speed and efficiency: CNC machining can be faster and more efficient than traditional manufacturing processes, as it eliminates the need for manual labor and can run unattended for long periods of time.

- Customization: CNC machining allows for easy customization of parts, making it ideal for low-volume production runs or one-off parts.

Disadvantages of CNC Machining

While CNC machining has many benefits, it also has some drawbacks that should be considered. These include:

- High startup costs: CNC machines are expensive, and the initial investment can be a significant barrier to entry for smaller companies or startups.

- Complexity: CNC machining requires specialized skills and knowledge to operate and program the machines, which can make it difficult to find qualified personnel.

- Limited production volumes: CNC machining is best suited for low to medium production volumes, and high-volume runs may be more efficiently produced using other manufacturing methods.

Selecting a CNC Machining Services Provider

When selecting a CNC machining services provider, there are several factors to consider to ensure that you get the best quality parts at the most competitive price. Some key considerations include:

- Expertise and experience: Look for a provider with a proven track record of delivering high-quality parts for your specific industry or application.

- Equipment and capabilities: Choose a provider with state-of-the-art equipment and a wide range of capabilities to ensure that they can handle all your manufacturing needs.

- Quality control: Make sure that the provider has a robust quality control process in place to meet the demand for product requirements and needs.

Machine Shop’s Near Me to Start with My CAD Model

When it comes to CNC machining, precision is key. Computer numerical control (CNC) machines are used to control and manipulate machine tools with a high degree of accuracy. CNC machining has become a vital process in many industries, from automotive and aerospace to medical and military.

At its core, CNC machining involves the use of a computer program to control the movements of a machine tool. This program contains instructions for the machine tool to follow, including information on the speed, position, and direction of the cutting tool.

The benefits of CNC machining are many. First and foremost, CNC machining allows for a high degree of precision and accuracy, which is critical in industries where even small errors can have serious consequences. In addition, CNC machines can work continuously, producing large quantities of parts quickly and efficiently.

Types of CNC Machining Equipment for Precision

There are many different types of CNC machines, each designed for a specific type of manufacturing process. Some of the most common types of CNC machines include:

- CNC mills – used for milling, cutting, and shaping solid materials like metal and plastic.

- CNC lathes – used for turning and shaping cylindrical objects.

- CNC routers – used for cutting and shaping wood, plastics, and other softer materials.

- CNC plasma cutters – used for cutting through metal and other conductive materials.

Steps to Get Machined Parts Completed – Turning, Drilling, Milling

Regardless of the type of CNC machine being used, there are several key steps in the CNC machining process. These include:

- Designing the part – Before a part can be machined, it must first be designed using CAD software. This software allows the designer to create a digital model of the part, including all of its dimensions and specifications.

- Programming the machine – Once the part has been designed, the CNC machine must be programmed with the necessary instructions for machining the part. This programming is typically done using CAM software, which translates the designer’s digital model into machine-readable code.

- Setting up the machine – Once the program has been created, the CNC machine must be set up to begin machining the part. This involves positioning the workpiece and the cutting tool, as well as ensuring that all safety measures are in place.

- Machining the part – With the machine set up and the program loaded, the actual machining process can begin. This involves the cutting tool moving along the workpiece according to the instructions in the program, shaping the material as it goes.

- Finishing and inspection – Once the machining process is complete, the finished part must be inspected for quality and any necessary finishing work, such as sanding or polishing, must be completed.

What’s Your Conclusion?

Overall, CNC machining is a complex process that requires specialized knowledge and expertise. However, the benefits of CNC machining are clear, from increased precision and accuracy to faster production times and greater efficiency.

If you’re looking to take advantage of the benefits of CNC machining for your own manufacturing needs, it’s important to work with a qualified and experienced CNC machining provider. With the right partner by your side, you can enjoy the advantages of CNC machining while ensuring that your parts are manufactured to the highest standards of quality and accuracy. Get your parts produced here at JawsTec to make sure you get the best quality support possible.

0 Comments