One of the many advantages of 3D printing is its quick turnaround time. While many other manufacturing techniques will take several days to produce a product, 3D printing can produce a product in a day. This results in a much more quickly filled order, a unique advantage that can make a difference for your project or business.

Whether you are looking to create custom parts for a larger project or produce a product for retail sales, inventory is one of the greatest challenges you face. Just In Time (JIT) inventory techniques are a great technique used to minimize costs and maximize organizational efficiency- and with 3D printing, it is easier than ever to implement JIT. Because 3D printing does not have batch requirements like many other methods, you can only order exactly what you need and with the very short time required to fill orders, you don’t have to store new inventory for long before you restock or use what you need.

With the JIT revolution coming to companies of all sizes, 3D printing is offering new answers, promising a whole new way of ordering and storing inventory. With less inventory sitting in storage and what there is sitting there for less time, resulting in a noticeable increase in efficiency. You can commit more space or funding to other parts of your business. By getting ahead of the 3D printing curve, you can have an edge on your competitors.

This quick turnaround time also makes 3D printing ideal for creating replacement parts, particularly if you are working with an unusual or older piece of equipment. Before, you may have to call manufacturers or parts shops to see if they had a part in stock. If you got lucky, one of them in the same county would or would be willing to ship the part from a faraway warehouse. With 3D printing, you just need to create (or work with an expert) to create a CAD file so your part can be printed to your exact specifications. No more calling around to see if your unique part is in stock! Just send in a file and your part will be printed and shipped to your front door.

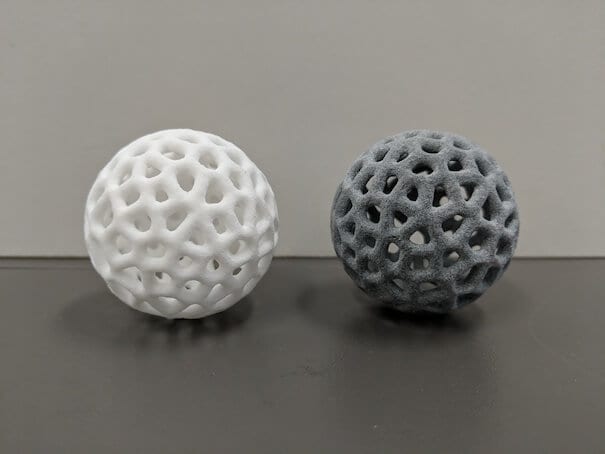

After your part is printed, it will need to go through some finishing in order to ensure that your product functions at its best. Finishing generally consists of post-production like sanding and heat-treating. This process typically takes a few hours and does not add much to the turnaround time. The exact length of the finishing process will depend upon the material used to 3D print your product.

At Jawstec, we can help you 3D print your products from the earliest stages of the CAD file design process to printing to finishing. Our expert team knows the ins and outs of the most up-to-date 3D printing processes. Jawstec’s facilities can print and finish products so that you receive the highest quality result. Get your project started here.

0 Comments