3D Printing of Prototypes

Head to JawsTec for any requirements you may have for prototype 3D printing.

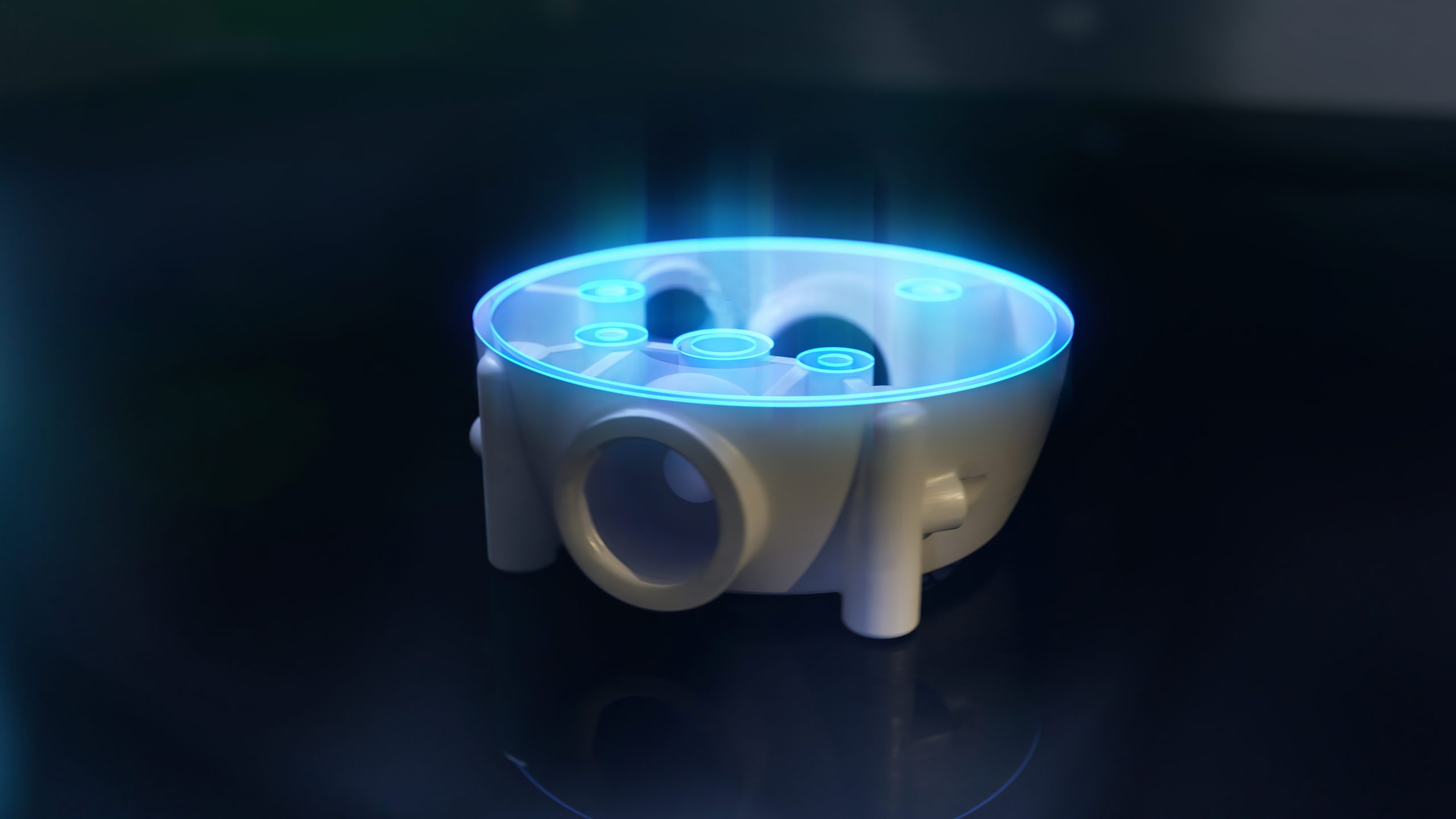

Rapid prototyping or Additive Manufacturing, more commonly known as 3D Printing of prototypes, has drastically changed the way prototypes are produced. It is now possible to generate high-quality prototypes quickly and cost-effectively, with no need to rely on slower, more expensive traditional manufacturing techniques. In this blog, we are going to explore the world of prototype 3D printing and its various applications, as well as its advantages and disadvantages.

The velocity of prototype 3D printing is a significant benefit that sets it apart from other prototyping processes. Generally, machining or molding will require weeks or months to come up with a single prototype. On the other hand, 3D printing can make a prototype in a matter of hours or even minutes, depending on the size and complexity. This rapid rate is very advantageous for those in design and engineering who have to try out various patterns in a brief time frame.

Prototype 3D printing offers an advantage in terms of its versatility. With conventional prototyping techniques, certain structures or components might be difficult or even impossible to generate. For instance, producing something with inner passageways or empty cavities through machining or molding may be complicated. Nevertheless, 3D printing makes it feasible to fabricate a broad selection of complex shapes and features without difficulty. This gives designers and engineers the freedom to be more inventive and explore fresh design choices that were previously beyond reach.

The precision of modern 3D printers is highly advantageous for creating prototypes, making them well-suited for a variety of applications. This is especially beneficial for manufacturing medical devices, aerospace components, and other objects that must adhere to exact dimensions and tolerances.

The advantages of 3D printing for prototyping are not limited to its swiftness, adaptability, and precision. For instance, designers and engineers can make multiple replicas of a prototype in a jiffy with no need of further tooling or preparation. Moreover, it is simple to modify the digital model and print a new version with the adjusted specifications.

Prototype 3D printing has its advantages, but there are certain restrictions to consider. For one, the range of materials available for 3D printing may not possess the same qualities as those used in traditional manufacturing. This can cause difficulty when prototypes need to be assessed based on strength, durability, and other physical properties. Additionally, the size of the objects that can be printed is often restricted to the size of the printer itself. Higher grade 3D printers can be used to print larger objects, but they come with a hefty price tag – in the thousands to hundreds of thousands of dollars. To get a good quality product for a low cost per part in prototyping, a 3D printing service is an excellent option.

Prototype 3D printing is gaining traction in numerous industries for producing prototypes, especially for intricate shapes or features, and for replicating them quickly and easily. As the technology improves and becomes more accessible, it is expected to become even more widespread in the future.

To sum up, 3D printing of prototypes is a revolutionary method that facilitates designers and engineers to produce high-quality prototypes expeditiously and simply. It provides numerous advantages, for instance speed, adaptability, and accuracy, and can be utilized in a broad range of sectors. Even though it has a few boundaries, it is conceivable that the popularity of 3D printing of prototypes will continue to rise as technology develops. Get in touch with us now or use our 3D print quotation tool to find out how we can assist you.

0 Comments