MJF 3D Printing Service

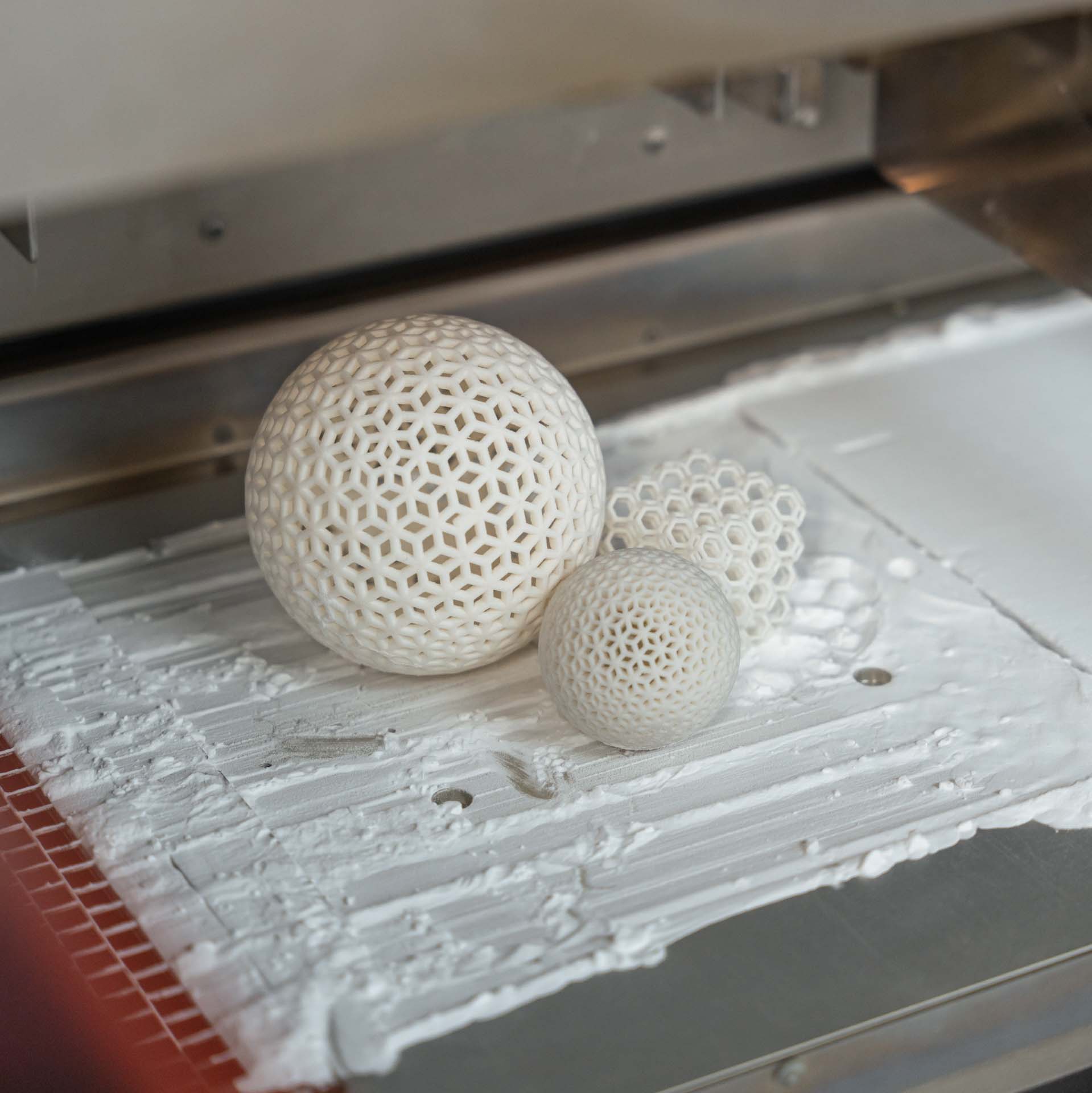

Multi Jet Fusion is a very common branch of 3D printing. It is useful in a wide variety of applications and projects, from ATV modification parts to office storage accessories. Read more about this service below.

What is Multi Jet Fusion?

The process of MJF printing is done by layering a polymer or nylon material powder into a powder bed of a 3D printing machine. Then, a binding agent is deposited as directed by the design file. Lastly, a laser runs over the powder bed, solidifying the design. This process is repeated until the part is complete.

MJF (Multi Jet Fusion) capabilities

Maximum build size |

Standard lead time |

Tolerance |

Layer height |

Minimum feature size |

| 380mm x 280mm x 380mm | 4-5 business days | (X,Y): +\- 0.300mm or 100mm +\- 0.3%

(Z): +\- 0.400mm or > 100mm +\- 0.4% |

80 μm | 1 mm |

MJF 3D printing processes use strong, versatile materials

That’s why a variety of industries use our 3D printing services and materials

Material |

Default Color |

Resolution |

Weaknesses |

Strengths |

Applications |

| Nylon PA 12 | Grey | 80μm | Occasional defects | Efficient cost | Prototypes, test parts |

| Nylon PA 11 | Grey | 80μm | Surface defects | Chemical resistance | Prototypes |

| Glass-Filled | Grey | 80μm | Higher cost | Excellent strength | Complex parts |

| Polypropylene | Dark Grey | 80μm | Oxidized degradation | Thermally resistant | Automotive parts |

| Full-Color | Colors | 80μm | Requires .3MF file | Perfectly colored parts | Particular custom parts |

Surface finishes for MJF 3D printing

We offer 3 types of surface finishes for MJF Printing

Raw

Part is taken from machine and excess powder is removed

Polished

Part is tumbled and then shot-peened providing a smooth surface

Vapor Polished

Parts are smoothed in a machine, providing an injection-molded surface look

How MJF stacks up against other 3D printing technologies

Materials |

Price |

Strengths |

Max. part size |

Layer thickness |

Min. feature size |

|

SLM |

Aluminum, 316L Stainless Steel, 17-4 Stainless Steel | $$$ | Metal parts | 400mm x 320mm x 320mm | 50µm – 200µm | 1 mm |

SLA |

Proto Plus, WaterTight, Smooth GP, Transparent Plus, Tough Plus, High Temp TS, Imagine Black | $$ | Smooth surface finish | 1380mm x 680mm x 480mm | 50µm – 200µm | 1 mm |

SLS |

Nylon PA12, Nylon PA2200, Thermoplastic Polyurethane (TPU) | $$$$ | High precision |

|

120 µm | 1 mm |

MJF |

Nylon PA12, Nylon PA11, GLass Filled Nylon, Polypropylene, Full Color(CBPA12) | $ | Strong structures | 380mm x 280mm x 380mm | 80 μm | 1 mm |

We have high standards for MJF 3D printing

Every part we manufacture is produced to meet the highest quality standards and your precise expectations. Our machines and printers are operated by teams of professional technicians and designers. When you work with us, you can expect each order to meet our Quality Policy. If you have any questions about our standards or quality certifications, please see this page or email us at [email protected].

Advantages and drawbacks of MJF 3D printing

Advantages

- Structurally strong parts

- Quick results

- Highly precise dimensions

- Minimal material waste

Drawbacks

- Default part color is dark grey

- Parts can only be dyed to darker colors

- Limited material options

Designing files for MJF printing

We can print your parts off almost any 3D CAD file, including .STL, .3MF, and .OBJ. The minimum dimension we suggest for your parts in 1 mm to help protect the quality of the print. We also offer in-house CAD file design assistance. For more information, email [email protected].

More resources for MJF 3D printing

Visit the links on the right to learn more about MJF 3D printing! Or, you can visit our blog to explore other helpful articles and information.

Want to learn more about MJF?

Our other 3D printing processes

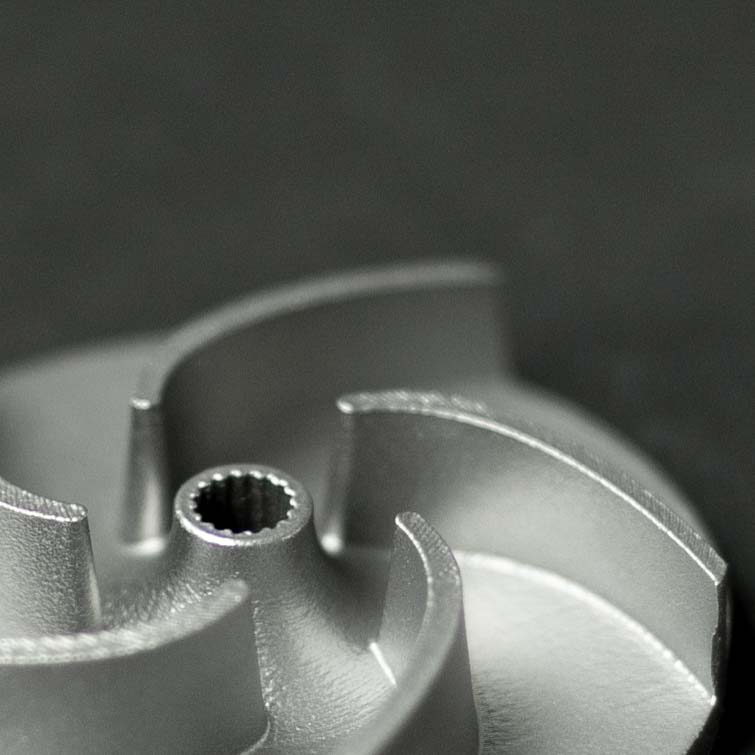

SLM

Need to print some metal parts? We’ve got you covered with our SLM printing technology.

- Lightweight metal parts

- Highly customizable metal parts

SLS

Looking for another option to print nylon parts? Check out the SLS process

- Dimensional accuracy

- Chemical resistance

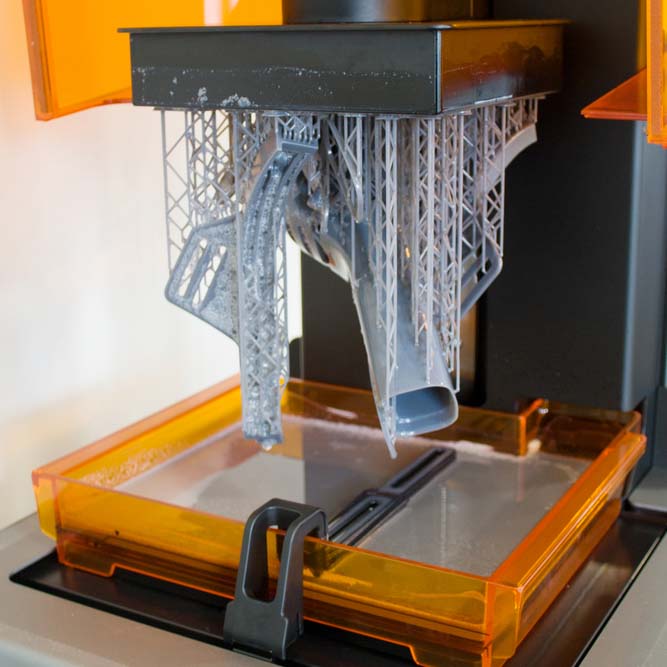

SLA

Want to try a whole new printing process? Take a look at SLA technology.

- Superior strength and durability

- Smooth raw surface