CNC machining services

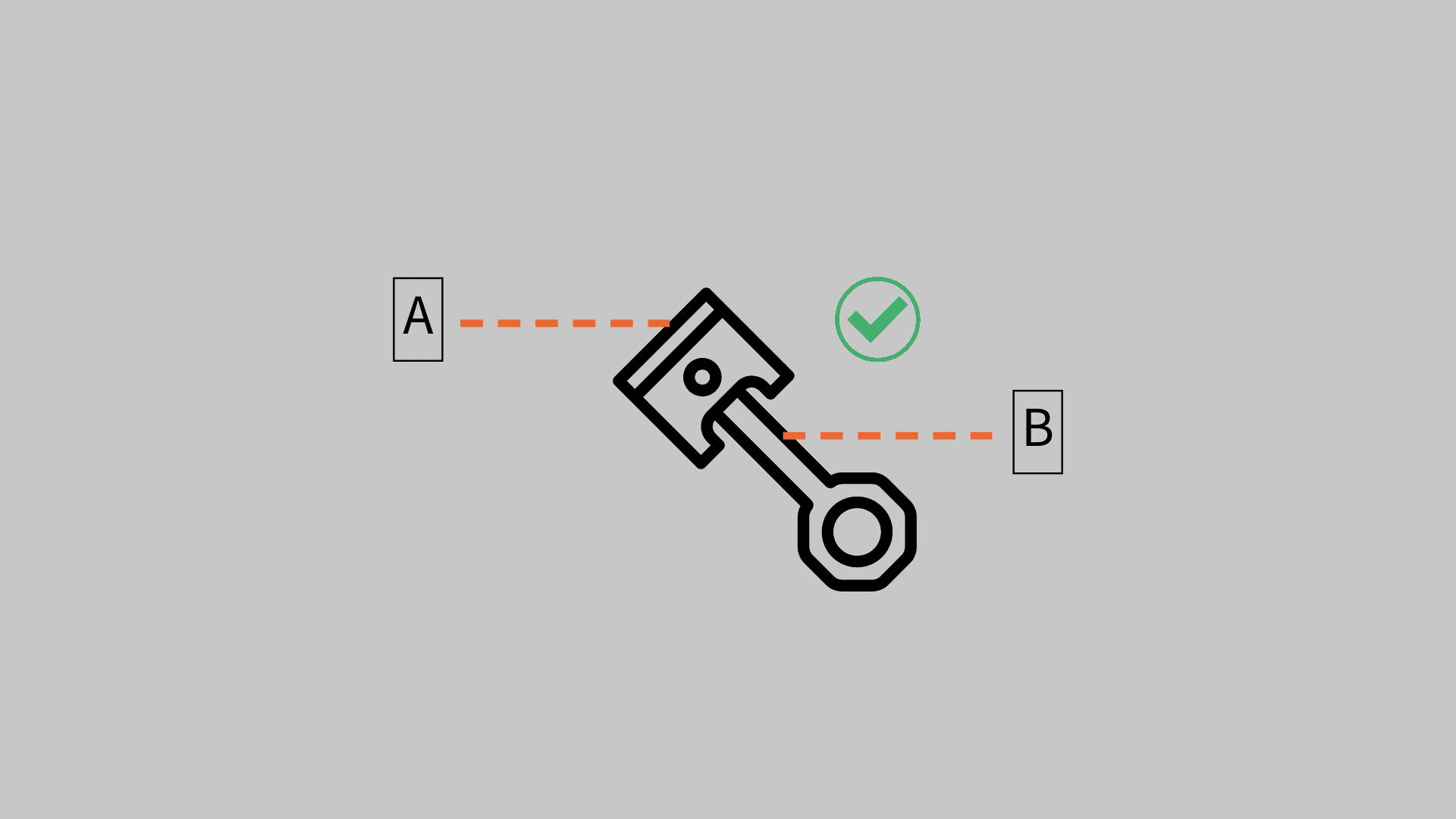

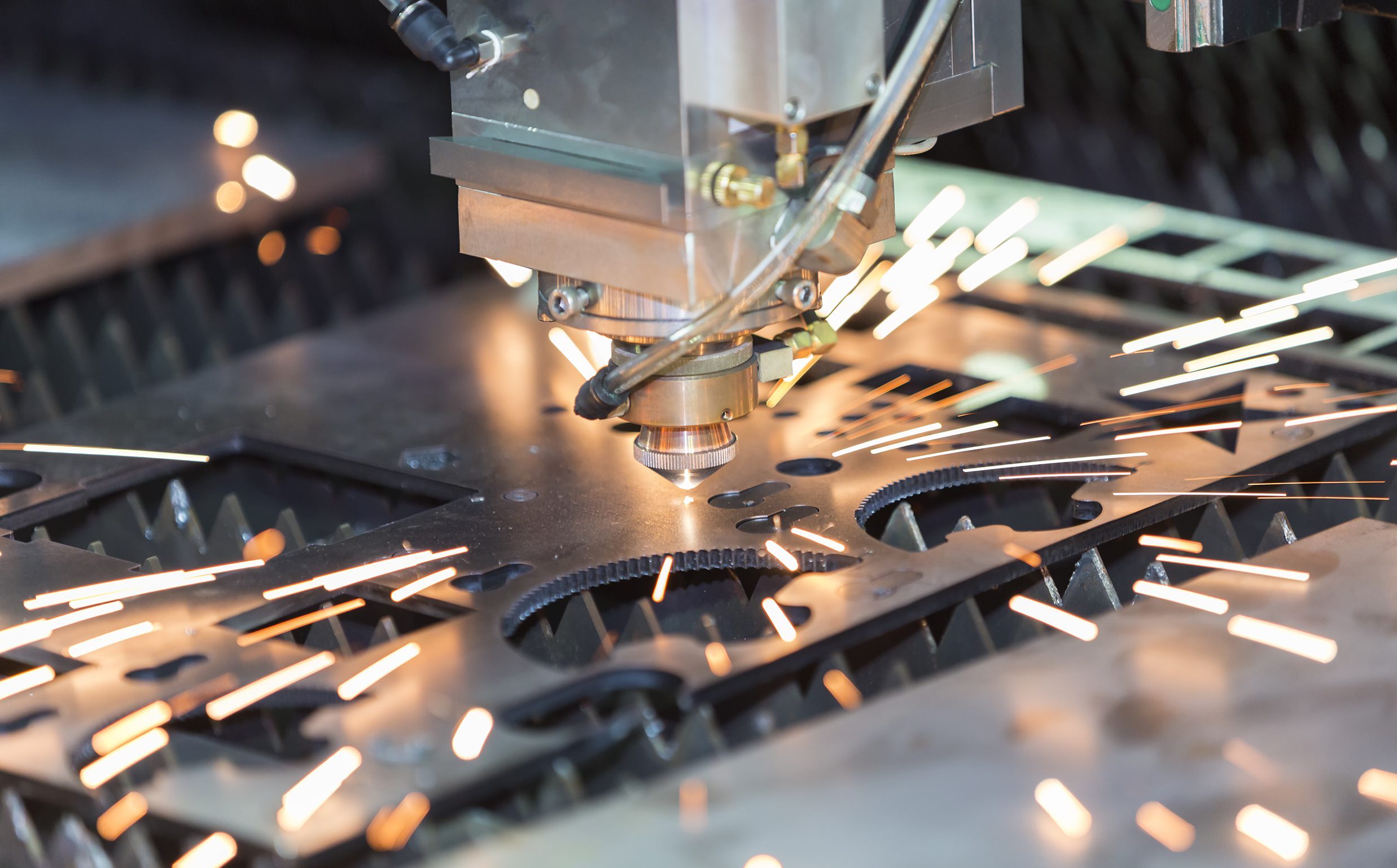

Computer Numerical Controlled manufacturing is one of the most efficient, quick, and effective ways to produce automotive parts like gears, pistons, and rods.

All Uploads are Confidential and Secure

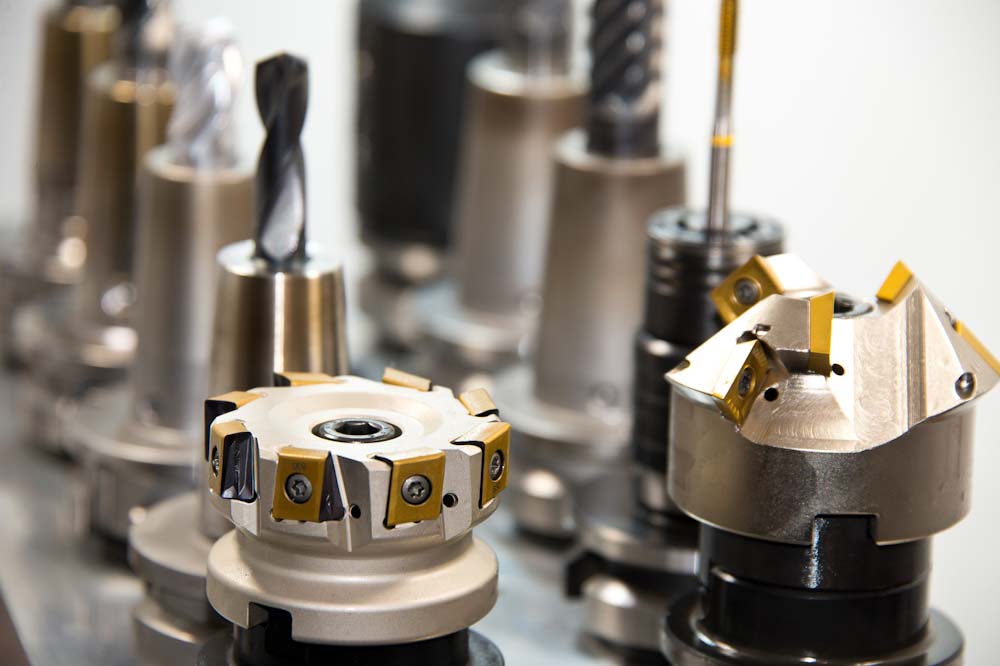

Our CNC machining capabilities

Our CNC machining services are professional-grade. Each machine is operated by our team of expert techs.

CNC Milling

Our machine shop uses industrial mills like the HAAS DM-2 and HAAS EC400 Mill to create high quality parts.

- Quick results

- Metal material options

- Highly precise

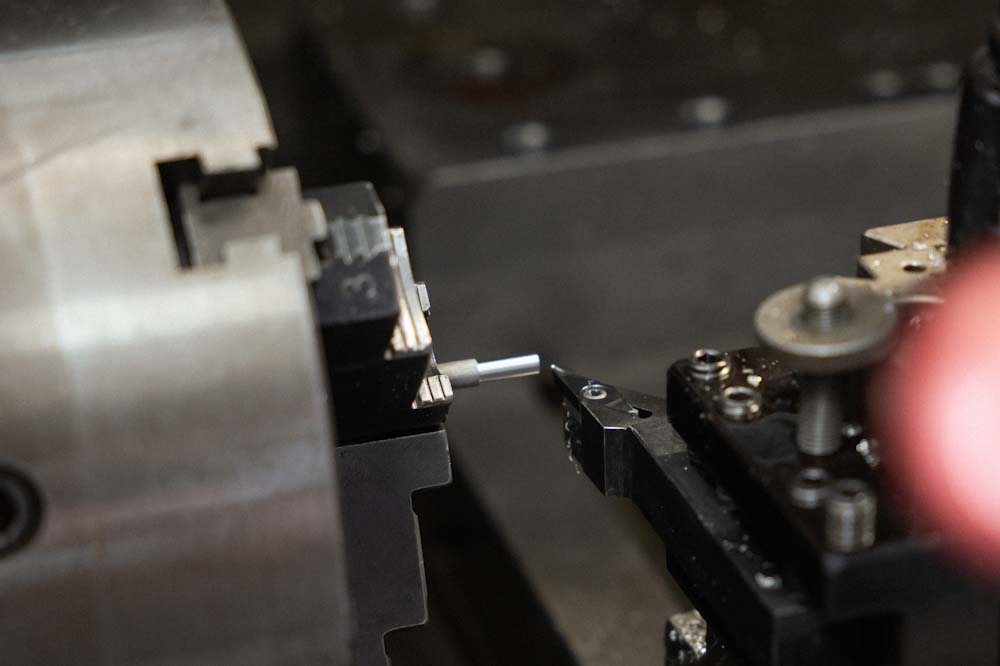

CNC Turning Lathe

Our HAAS SL-30 and Trak 1840 Lathes machine precision parts for protoypes or large quantity orders.

- Easily design prototypes

- Test designs

- Production-size runs

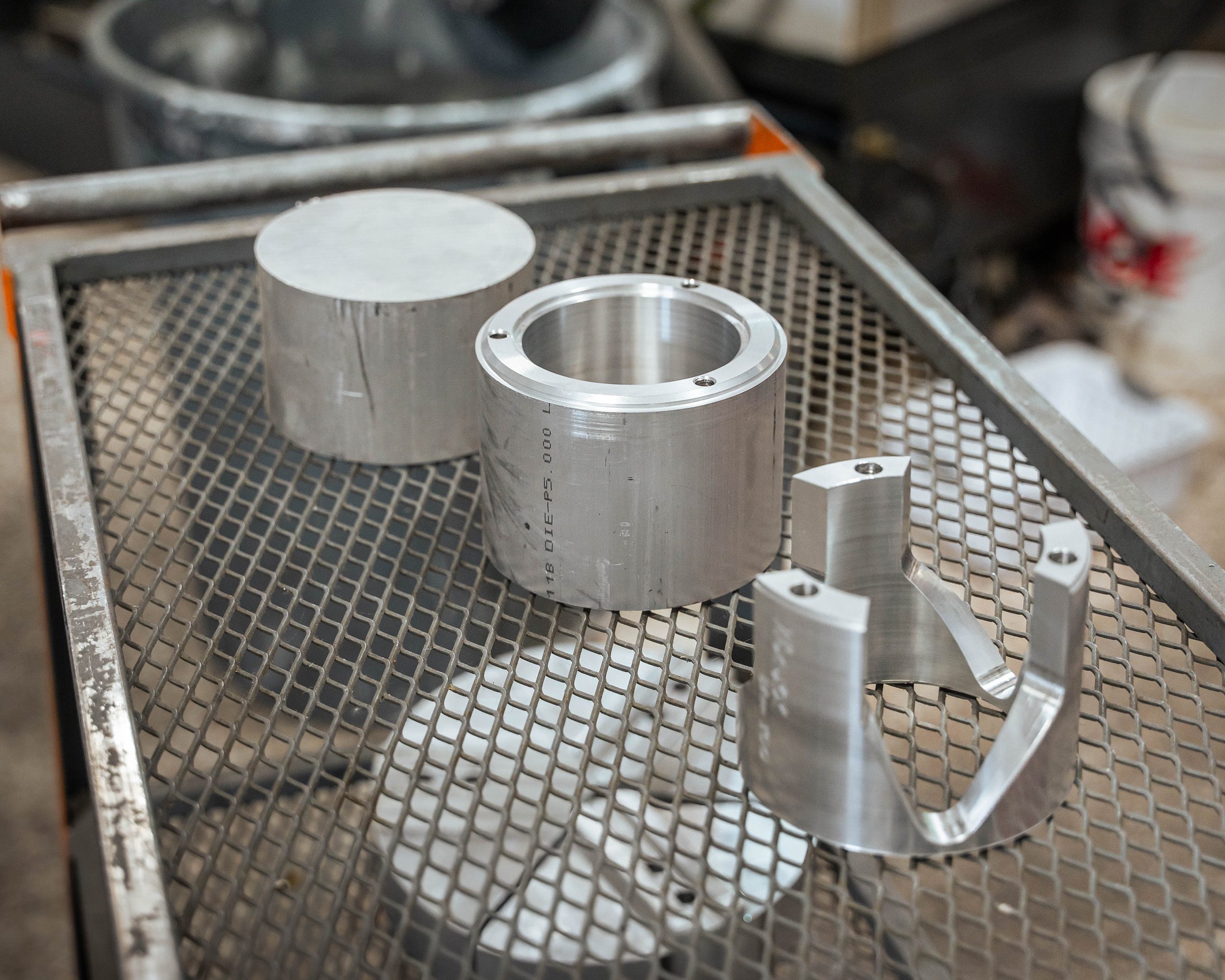

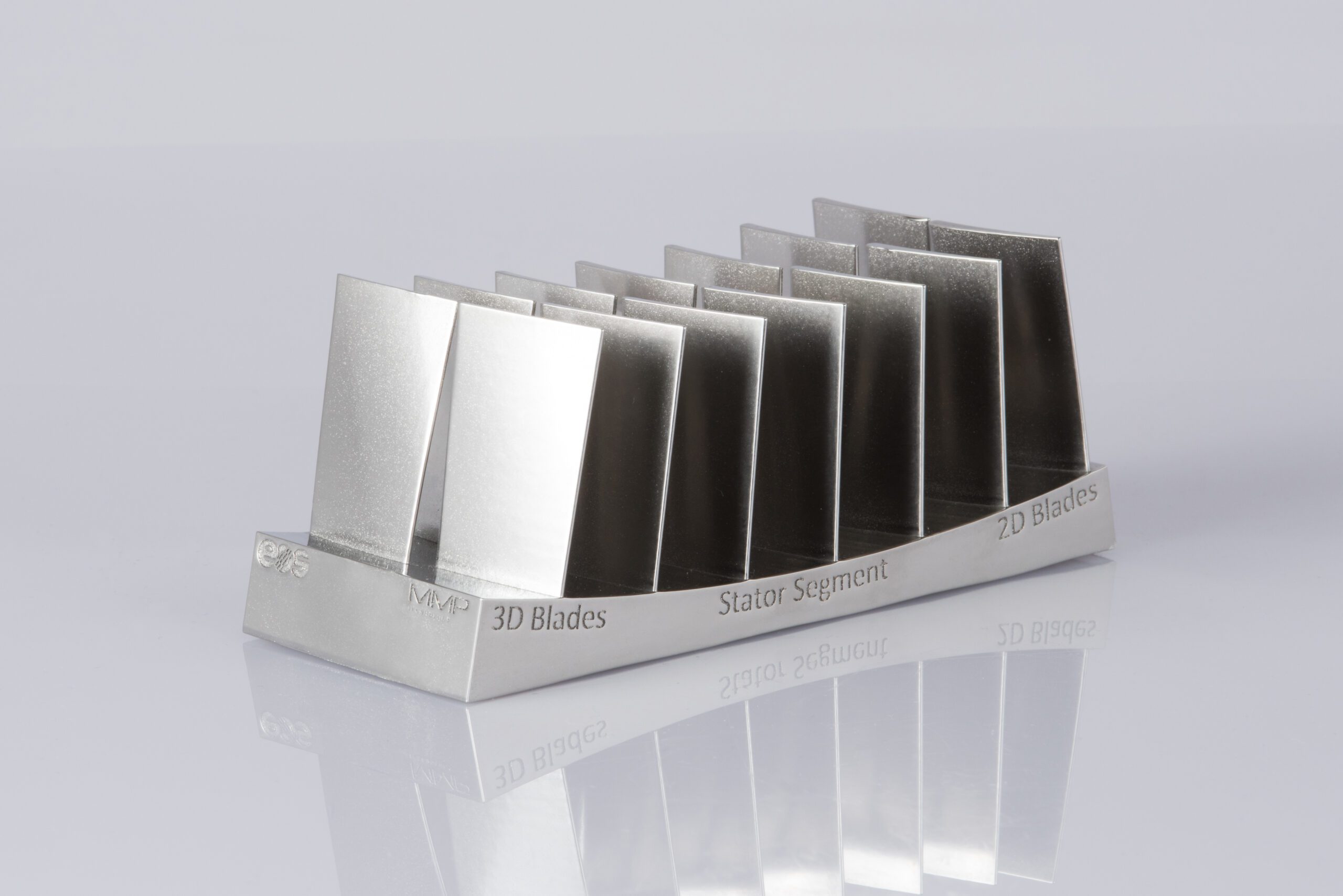

Gallery of CNC machined parts manufactured by JawsTec

View some examples of parts we have produced with CNC Machining

Materials for CNC machining

Choose from a variety of metal and hard plastic materials for CNC parts

| Aluminum |

| Aluminum 6061 |

| Aluminum 7075 |

| Stainless Steel |

| Stainless Steel 304 |

| Stainless Steel 303 |

| Stainless Steel 316 |

| Stainless Steel 17-4PH |

| Mild Steel |

| Mild Steel 1018 |

| Mild Steel 1045 |

| Mild Steel A36 |

| Tool Steel |

| Inconel |

| Tool Steel A1 |

| Tool Steel A2 |

| Copper/Brass |

| Copper C101 |

| Brass C360 |

| Copper C110 |

CNC machining surface finishes

Choose from a variety of post-machining surface finishes.

As machined

Slight appearance defects, raw finish, small marks and scuffs visible

Anodized

Addition of thin, non-corrosive layer, smooth, pleasing surface

Powder Coated

Addition of thin paint layer, protective, available in many colors

Bead Blasted

Uniform matte finish, visual improvement, removes tool marks

Hard Coat Anodizing

Thicker surface coat, not colored, tight tolerances can be maintained

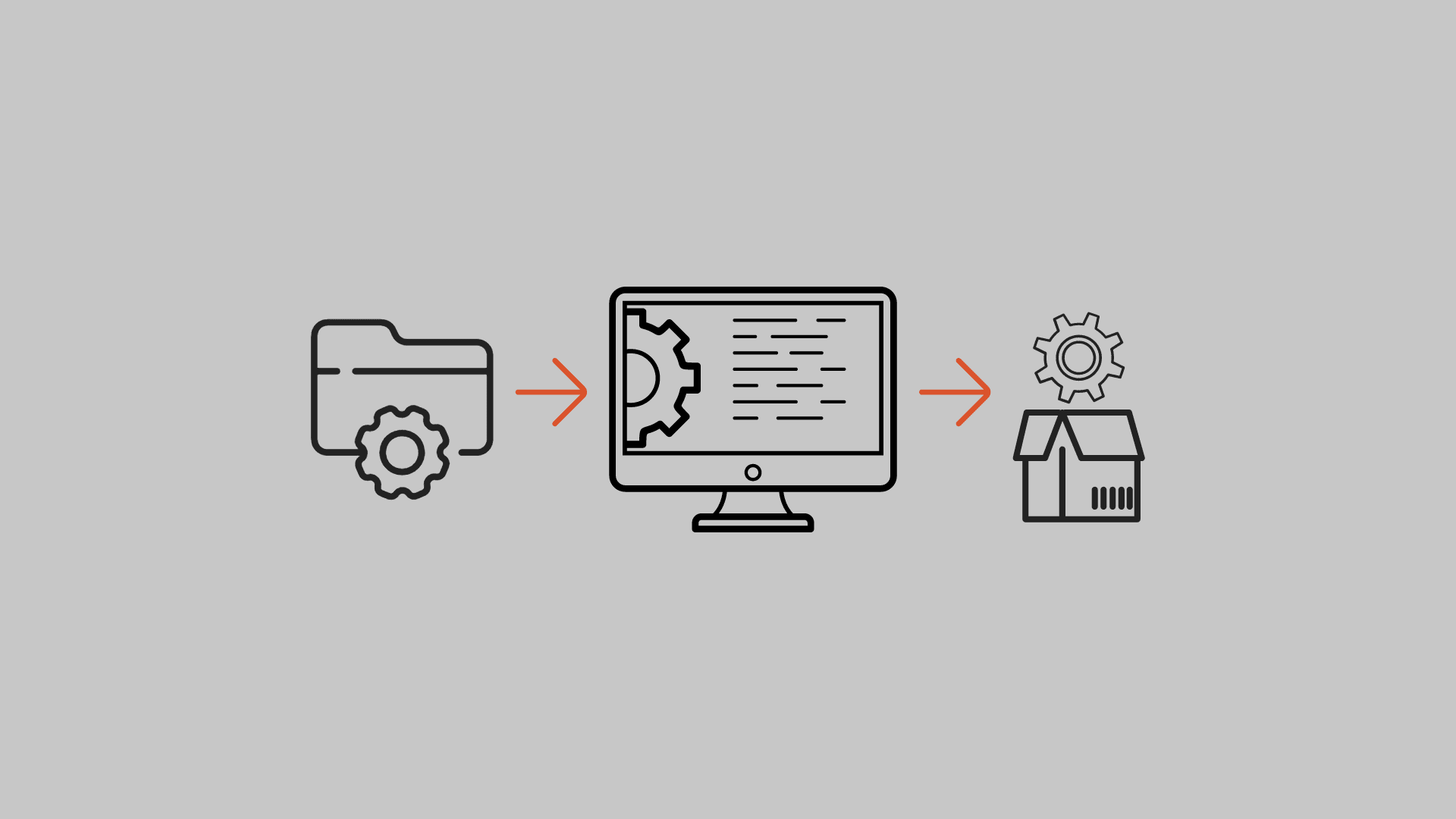

JawsTec’s ordering process

Upload your files to our CNC quote page, be sure to specify all the details of your project. We will get back to you with a quote shortly.

Your parts will be put into production and will be professionally processed and finished. We will ship the parts according to your shipping selection at checkout.

Receive your parts at your doorstep and put them to use! Keep JawsTec in mind for your next CNC project.

Industries JawsTec specializes in

Each of the following industries utilize JawsTec’s CNC machining capabilities

Industrial Machinery

Gears, rods, duct attachments, levers, operative systems, mechanical parts

The JawsTec Standard – Unwavering Quality, Consistently Delivered

No matter the process, material, or order, here at JawsTec we guarantee every part will meet your expectations. If you are unsatisfied with your parts, we will work to make it right.

Instant production

As soon as we receive your quote request and process your payment, your parts will go into production. Most CNC orders can be completed within 20 days of ordering. Learn more about the production process below.

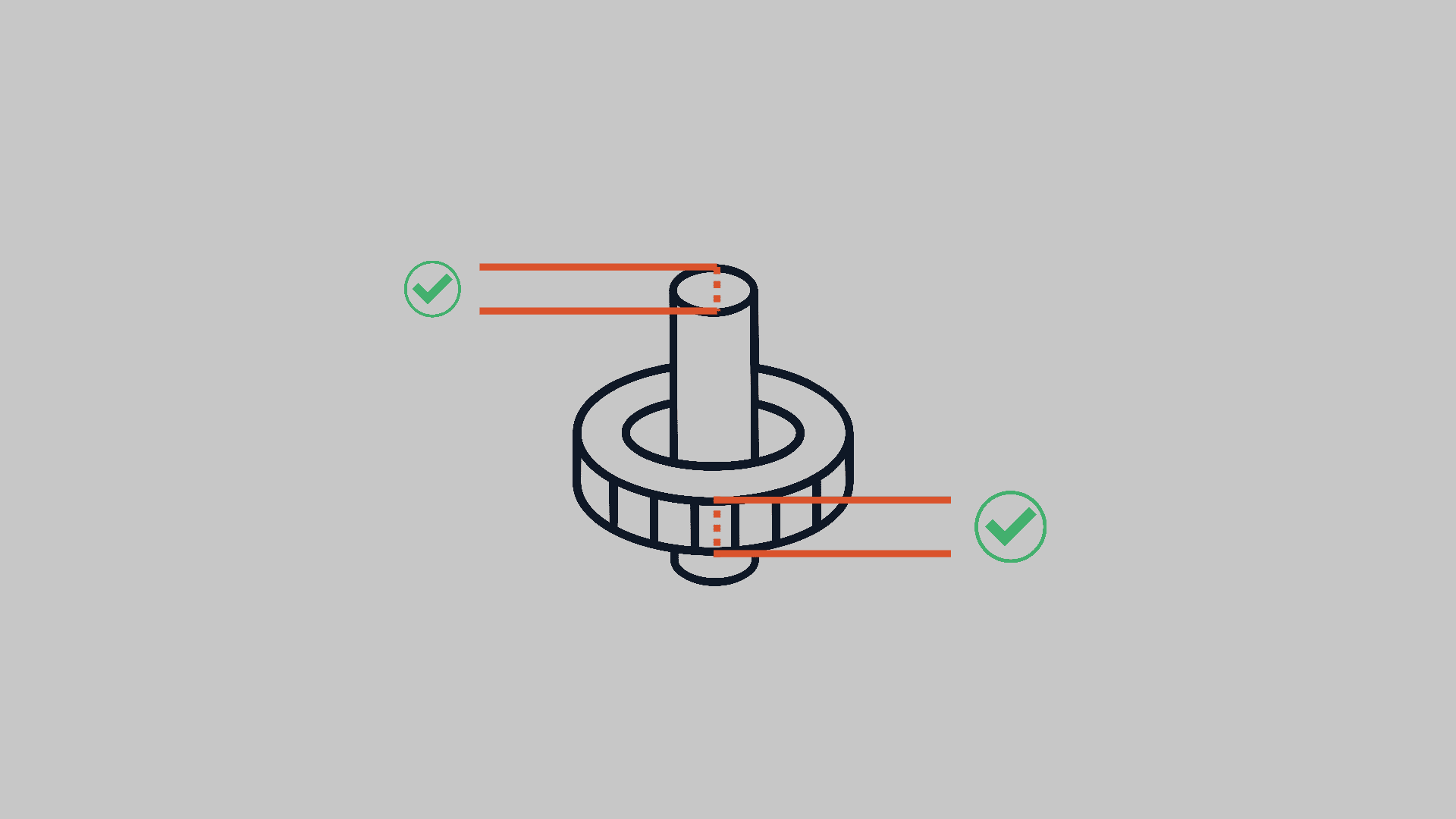

Dimensional accuracy

CNC machining provides unmatched dimensional accuracy when producing your parts. Tolerances vary depending on material, but are always minimal, and each material is highly precise.

Cosmetic standards

We offer a variety of cosmetic and functional finishes for our CNC parts. You can order raw, anodized, powder coated, bead blasted, or hard-coat anodized finishes on your parts.. Learn more below.

From CNC rapid prototyping to production

Rapid prototyping

CNC machining can be a great option for your rapid prototyping needs. It will produce a part off your CAD files, which can easily be adjusted to account for design changes after testing. Put your parts into production today and start testing the designs for your next project.

Production

CNC machining also provides a way to quickly make production runs for your parts. With large and small batch capabilities, all your needs can be covered, no matter the scale of your operation. We can also apply finishes to your CNC parts to give them a professional, ready-to-use appearance.

Get started with CNC machining

How do you start CNC machining parts with JawsTec?

Request a quote today. Place an order after making final adjustments to your files. Receive your parts ready-to-use after processing is done.

How does JawsTec’s custom CNC machining service work?

Your parts are custom made to fit your specifications and standards. Place an order today to experience the difference when you create with JawsTec.

FAQ’s

FAQ 1: What kind of files do I need for a CNC project?

We can use .step, .stl, .stp, or zip files.

FAQ 2: Do you offer certifications for CNC parts?

We offer material, dimension, and finish certifications.

FAQ 3: Can you 3D scan off another object?

We do not offer this service at this time.

FAQ 4: Can I get my CNC parts colored?

If you get an anodized finish on your parts, you can get them colored.

FAQ 5: What is the estimated turnaround time for CNC orders?

Most CNC orders can be completed within 20 business days of ordering.

CNC machining resources for engineers

CNC Manufacturing in Today’s Industries

Read about the effect of CNC technology on industries from the automotive, to aerospace, to defense, to electronic industries. This article also talks about the role of AI and IoT in CNC technologies. Read the whole article below.

Comparing 3-Axis and 5-Axis CNC Processes

Read about the best applications for 3 and 5-axis CNC machines. Learn about the uses for X,Y, and Z versus X, Y, Z, A, and B rotational axes. This article also talks about the advantages and disadvantages of both.

Ultimate Guide to CNC Machining

Read about the history of CNC machining, from the 1940’s to today. Learn about the advantages of CNC processes over traditional manufacturing methods, as well as the different types of equipment for CNC projects.

Precision CNC Manufacturing

Read about the benefits of CNC Manufacturing and how precise the processes can be. Learn about the best types of projects for CNC machining and how CNC technology can optimize your business for best performance.

Our other manufacturing capabilities

3D printing

Get your parts made easily with 3D printing. This process works by layering a polymer powder and solidifying it with a laser. Available in many colors, materials, and processes.

Sheet metal fabrication

Sheet metal fabrication processes work by using either a laser or waterjet to cut and shape metal sheets, as well as bending them to shape. Available in a range of metals, finishes, and colors.

Injection molding

A traditional manufacturing method, injection molding is best for large, production-size orders. It can be done with different materials and requires a pre-formed mold to be injected with the molten material.