CNC milling service

Computer Numerical Controlled milling processes allow you to create your parts with maximum design flexibility, precision, and accuracy.

What is CNC milling?

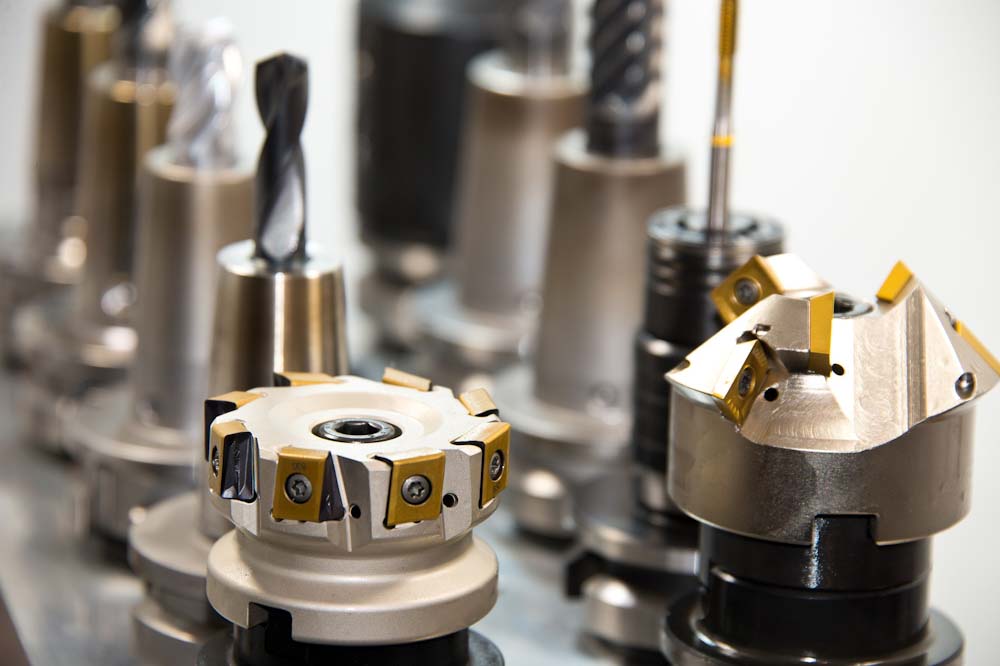

The CNC milling process takes a piece of hard material, such as metal or plastic, and cuts out the desired part with a rotating cutting tool.

Parts milled with CNC machines often require a post-processing treatment to preserve the quality and surface appearance. These finishing options include anodizing, raw, and bead blasted.

Whatever the needs of your CNC project, you can find resources to help you accomplish each aspect and reach your goals.

Maximum part size for 3- and 3+2-axis CNC milling

At JawsTec, you can expect quality parts and services no matter what process you choose to use.

3-axis milling

Machine |

Max table weight |

Number of axis |

Minimum wall thickness |

| HAAS DM-2 | 113 kg | 3: X, Y, Z | 1 mm |

Maximum part size for 5-axis CNC milling

5-axis milling

Machine |

Max table weight |

Number of axis |

Minimum wall thickness |

| HAAS EC-400 | 113 kg | 5: X, Y, Z, A, B | 1 mm |

CNC Milling Material Options

Material |

Default Color |

Weaknesses |

Strengths |

Example Applications |

| Aluminum | Silver | Heat resistance issues | Great strength to weight ratio | Medical devices |

| Stainless Steel | Silver | May corrode easily | Extremely versatile | Kitchen appliances |

| Steel | Dark grey | Requires surface treatment | Cost efficient | All major industries |

| Copper | Reddish orange | May naturally oxidize | Naturally antimicrobial | Thermally conductive parts |

| Titanium | Light grey | Specific design requirements | Biocompatible | Chemical processing industries |

| Inconel | Silver grey | Geometric design restrictions | Resistant to corrosion | Technical aerospace parts |

| Brass | Light gold | Can be damaged by weather | Easy to machine | Home decor accents |

| Plastic | Varies | Warping can occur from heat | Low cost for design testing | Prototyping |

CNC milling surface finishes

We offer 5 main types of surface finishes for your CNC parts.

Bead Blasted: The bead blasting finish process creates a uniformly smooth surface on the part. It can be matte or satin in appearance, and will be best for cleaning up surface marks and cosmetic appearances. Areas of the part with crucial size tolerances can be masked and preserved.

As Machined: As machined parts are left with a raw surface finish. This means that small machining marks and scratches can remain and will be visible. The standard surface roughness of as machined parts is 3.2 μm (125 μin) and can be decreased down to 0.4 μm (16 μin) with further operations with finer end mills.

Polished: With the polished finish, parts are given a shiny and smooth appearance. Surface marks will not be visible and the whole part is cleaned up.

Anodized: Anodizing adds a smooth, non-conductive surface coat to the parts. It results in an aesthetically pleasing surface that can be dyed to different colors.

Hard-Coat Anodized: Hard-cost anodizing gives parts a thicker surface coat. This thicker coat is more protective and preserves better against corrosion.

CNC milling tolerances

CNC machining allows for the tightest tolerances possible

CNC Milling Design Guidelines

Designing CAD files for CNC milling is much different from designing for 3D printing. With milling projects, it is important to understand how each different materials behaves and will react when being cut or treated with a surface finish.

Also, you will want to consider the final intent for your project. If it is going to be used outside, you may want to use a particular surface finish that will stand up to weather elements better. On the other hand, if your parts are for electrical purposes, you will want a material that conducts electricity.

Feature |

Recommended metric size |

| Min. feature size | 2.5 mm |

| Min. text font size | 20 |

| Min. wall thickness | 1 mm |

| Min. hole diameter | > 1 mm |

| Min. thread size | M1 |

Why should you choose CNC milling?

Why should CNC Milling be a part of your company’s processes?

CNC milling is beneficial to any business that requires part supply, replacement parts for machines, or other type of manufacturing needs. It can produce a custom, precision-made piece that integrates perfectly into your machine or daily processes.

In addition, CNC milling processes are available in many different materials, surface finishes, and technical requirements. If you have any questions about your project or how CNC milling can help your business, please reach out to us at [email protected]. You can find out more at the link below.

We have high standards for CNC milling

What kind of standards are set for your CNC milling processes?

As with any process we offer here at JawsTec, we hold our parts to the highest standards. Our Quality Policy offers a satisfaction guarantee on your parts and if you are not happy with what you receive, we will work with you to make it right.

Our professional technicians operate our milling machines and work on your order from start to finish. Whatever specific needs or project requirements you have, we are happy to work with you to produce the best results possible.

More resources for CNC milling

Learn more about CNC milling and the different material options we offer.

Our other CNC machining process

CNC turning

The CNC turning process allows you even more flexibility and design capability. It is also perfect for larger batch orders. You can learn more about this option at the link below.