CNC machining materials

Stainless steel CNC machining service

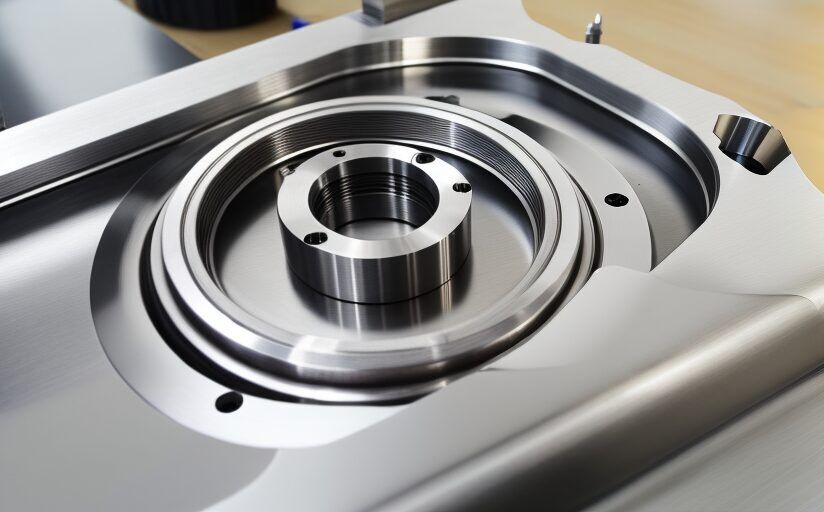

CNC Machining Stainless Steel is a modern way to produce parts and products for you or your company.

CNC Stainless Steel

Stainless Steel is an extremely versatile type of metal used in CNC machines.

Description

| Applications | Some common uses of stainless steel are surgical tools, automotive gears and levers, kitchen appliances, and mechanical parts. |

| Strengths |

|

| Weaknesses |

|

Characteristics

| Price | $$$$$ |

| Lead Time | 20+ business days |

| Wall Thickness | 1 mm |

| Tolerance | .127 mm |

| Max table weight | 113 kg |

Available materials

Stainless Steel 304

Stainless steel 304 has a lower cost compared to other types of stainless steel. It also is better at corrosion resistance than other variations. Another plus of 304 is it;s improved strength and durability properties.

Stainless Steel 303

Stainless Steel 303 is less corrosion resistant than other variations. It is also easier to machine. This material is perfect for projects that are heavily detailed like gears and shafts and will require precision.

Stainless Steel 316

Stainless steel 316 is extremely corrosion-resistant. It is also easy to weld and form, which makes it flexible for working into big projects. This material is a good option for boat fittings and chemical-related projects.

Stainless Steel 17-4PH

Stainless steel 17-4PH is precipitation hardened, which means that it is more corrosion resistant than other options. However, it is generally less mechanically sturdy than other material options. It can be used for chemical projects or turbines.

Stainless steel CNC machining services

JawsTec’s Stainless Steel CNC services are waiting for you to take advantage of them in your next project. We back each product with our Quality Standards, which you can read about here. We encourage you to reach out to us if you have any questions about the ordering process, CAD files, or CNC machining in general.

FAQ’s

FAQ 1: Do you offer CAD design work?

We have an in-house CAD file designer available to hire starting at $50/hour. Email [email protected] for more information.

FAQ 2: What CNC processes do you offer?

We have CNC milling machines and CNC turning lathes.

FAQ 3: What types of finishes do you offer for CNC parts?

We can leave your parts as-machined, or andonize, powder coat, bead blast, or hard coat andonize them. You can specify the finish you want when placing your order.

FAQ 4: What CNC material types do you offer?

We offer several variations of each type of material: aluminum, stainless steel, alloy steel, mild steel, tool steel, titanium, copper, brass, and plastic.

FAQ 5: Do you offer rush production?

Rush production is available for CNC orders. You can specifiy rush production when placing your order.

FAQ 6: What process is CNC considered to be?

CNC is considered to be a subtractive process, since it works by cutting away at a block of material to form the desired object.

FAQ 7: What does CNC stand for?

CNC means Computer Numerical Control. This refers to the manner in which a computer is programmed with numbers to create the part.