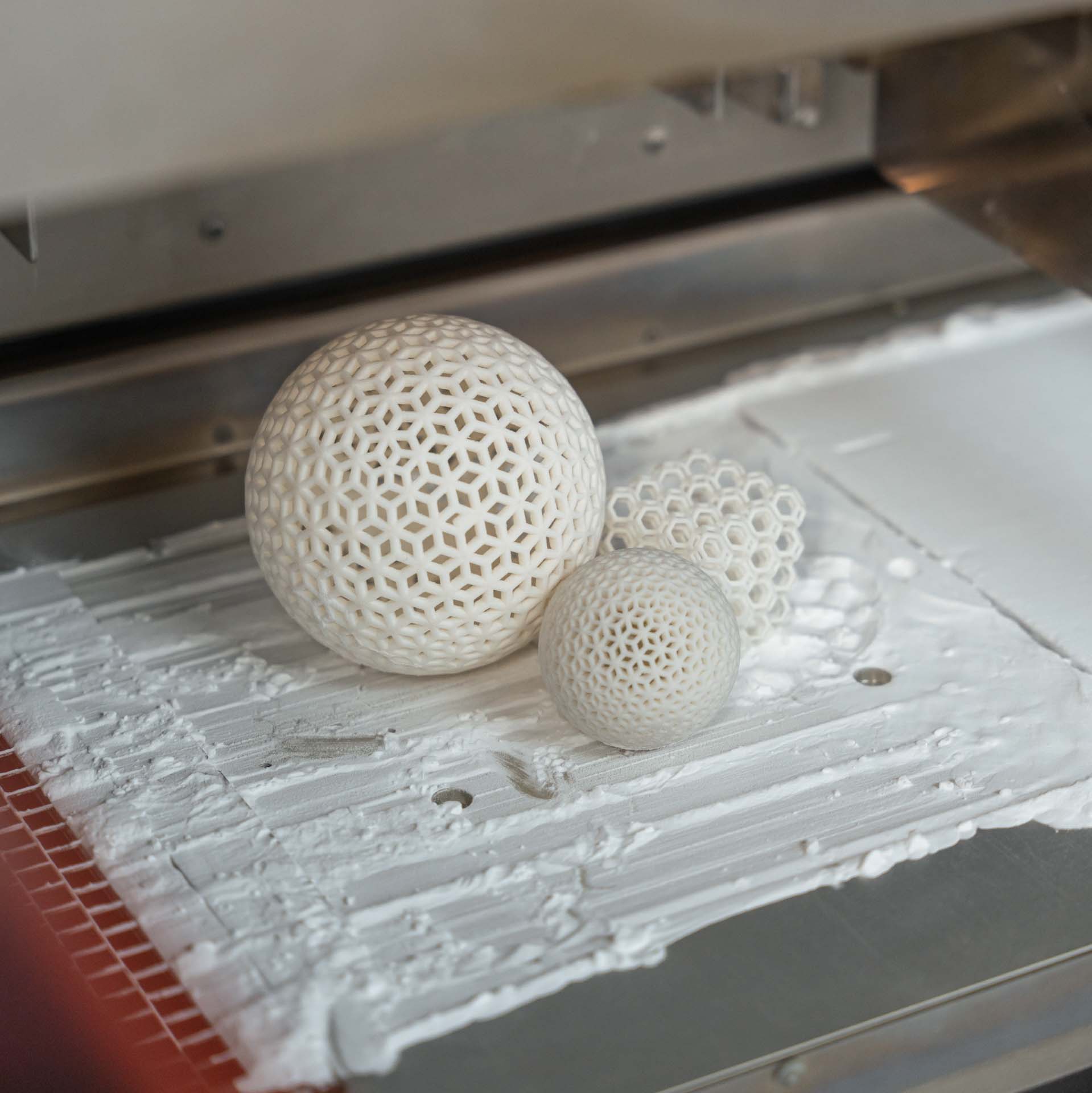

SLM 3D Printing Service

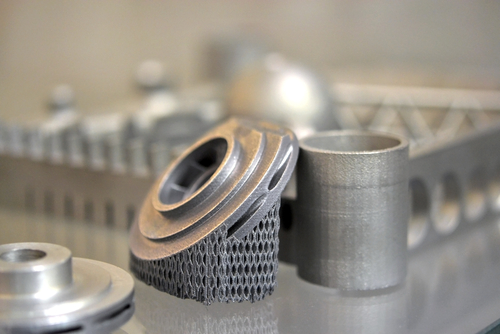

With Selective Laser Sintering technology, you can get 3d printed parts in metallic materials. Here at JawsTec, we offer a variety of options for SLM printed parts.

What is SLM 3D printing?

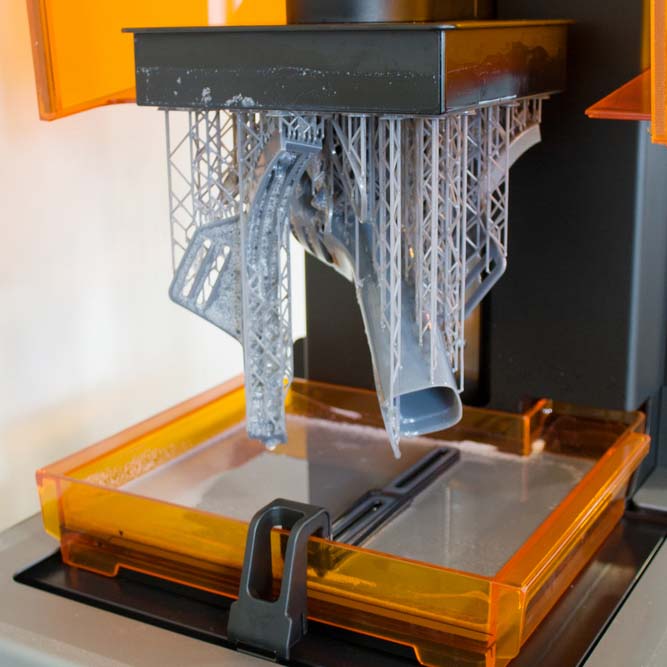

Selective Laser Sintering technology allows you to 3D print objects in metal materials. The process involves layering a powder that is infused with a metallic substance and then solidifying it in the desired shape. The shape is determined by the printer as it reads off the CAD file you designed and uploaded to our quote page.

SLM printing is a great way to acquire custom metal parts at an efficient price and in a convenient way. We guarantee your satisfaction with each order!

SLM 3D printer capabilities

Maximum part size |

Standard lead time |

Tolerance |

Layer height |

Minimum feature size |

| 400mm x 320mm x 320mm | +/- 20 business days | +/- 200 µm | 50 µm – 200 µm | 1 mm |

SLM 3D printing materials

Compare all our options

Material |

Default Color |

Weaknesses |

Strengths |

Applications |

| SLM Aluminum AlSi10Mg | Silver/Grey | Cannot be dyed, longer lead time, higher cost | Corrosion resistant, thermally conductive | Medical, technical, consumer products |

| SLM Stainless Steel 17-4pH | Silver/Grey | Longer lead times, surface hardness may vary | Chemical resistant, structurally supportive | Shafts, engine parts, mechanical parts |

| SLM Stainless Steel 316L | Silver/Grey | Longer lead times, surface hardness may vary | Can be welded if necessary | Medical prototypes, aerospace designs |

Post-processing for SLM

All SLM parts are attached to a base plate via the use of structural supports. These supports will be removed during post-processing.

SLM parts may also require heat treatment to improve the mechanical properties of your parts. Other post processing options include quality inspections and other solutions to improve your parts.

How SLM stacks up against other 3D printing technologies

Materials |

Price |

Strengths |

Max. part size |

Layer thickness |

Min. feature size |

|

SLM |

Aluminum, 316L Stainless Steel, 17-4 Stainless Steel | $$$$ | Metal parts | 400mm x 320mm x 320mm | 50µm – 200µm | 1 mm |

SLA |

Proto Plus, WaterTight, Smooth GP, Transparent Plus, Tough Plus, High Temp TS, Imagine Black | $$ | Smooth surface finish | 1380mm x 680mm x 480mm | 50µm – 200µm | 1 mm |

SLS |

Nylon PA12, Nylon PA2200, Thermoplastic Polyurethane (TPU) | $$$ | High precision |

|

120 µm | 1 mm |

MJF |

Nylon PA12, Nylon PA11, GLass Filled Nylon, Polypropylene, Full Color(CBPA12) | $ | Strong structures | 380mm x 280mm x 380mm | 80 μm | 1 mm |

Why should you choose SLM 3D printing?

What will SLM printing technology do for you?

SLM printing can help you acquire custom metal parts easily and painlessly. We will deliver them on time and to your exact standards.

This process can benefit your company by providing…

- custom metal parts

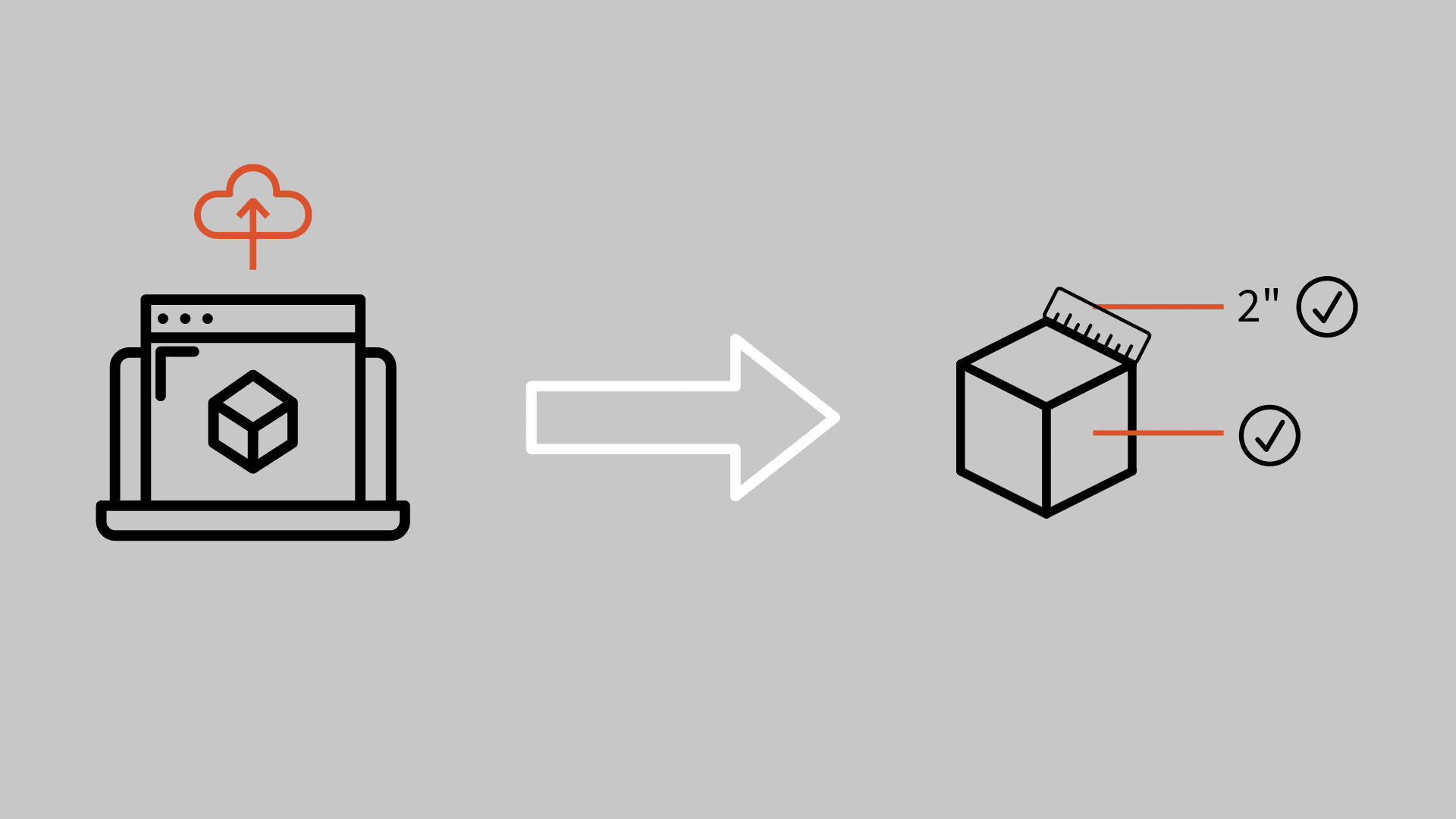

- a simple online ordering system

- chemically resistant metal parts

- corrosion resistant metal parts

We have high standards for SLM 3D printing

When you upload your files to our quote engine, you can expect top quality service. Our JawsTec Standards are professional-grade and guaranteed to meet your expectations. We promise to deliver your parts quickly and according to your specifications.

Read more about our RMA process, material certifications, and quality requirements here.

Advantages and drawbacks of SLM 3D printing

Advantages

- Highly customizable

- Lightweight structural parts

- Corrosion and chemically resistant

Drawbacks

- Longer production times

- More costly than 3D printing

- Cannot be dyed or colored

Designing files for SLM printing

When designing files for SLM printing, it is important to keep some design guidelines in mind.

- Keep your wall thicknesses over 1 mm

- Hole diameters should be at least 1 mm

- Make text clear and easy to print

- Unsupported features should be at least 1 mm in width

- Pins should be at least 1 mm in diameter

- Rounded corners work best

More resources for SLM 3D printing

Visit the links on the right to learn more about 3D printing with metal material! Or you can visit our blog to explore other helpful articles and information.

Our Other 3D printing processes

SLA

Want to try a whole new printing process? Take a look at SLA technology.

- Superior strength and durability

- Smooth raw surface

SLS

Looking for another option to print nylon parts? Check out the SLS process

- Dimensional accuracy

- Chemical resistance

MJF

Looking for a cheaper 3D printing option? MJF is the way to go.

- Faster lead times

- Color options