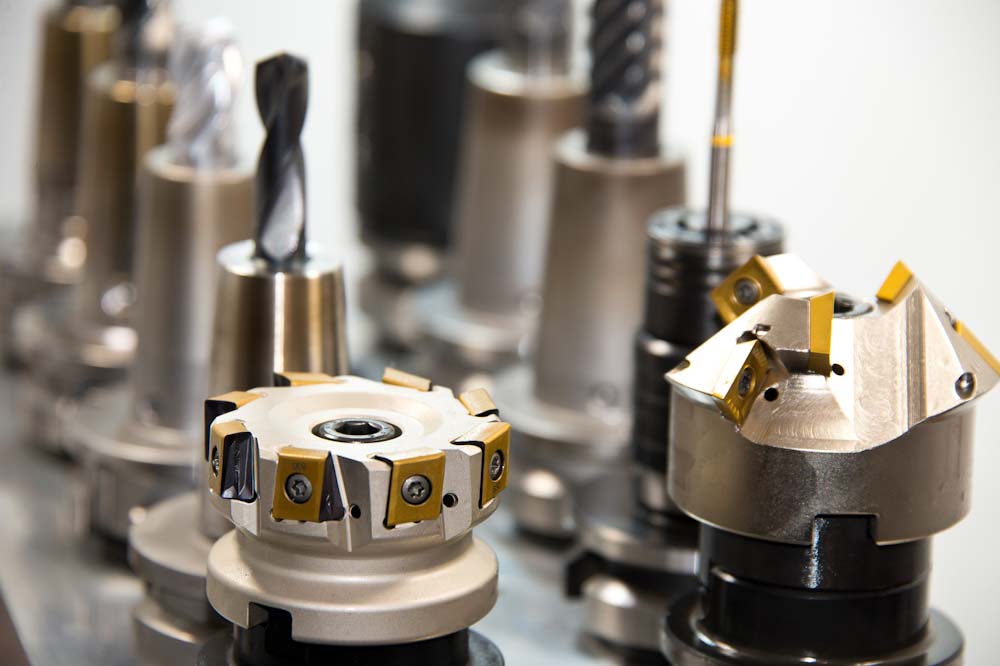

CNC machining materials

JawsTec offers a wide range of CNC machining materials, including metals and plastics, meticulously crafted to exact specifications for superior precision and performance in diverse industrial applications.

Metal & plastic CNC machining materials

Name |

Description |

Price |

||

|

Aluminum | Excellent strength-to-weight ratio and very durable. | $$$$$ | View aluminum materials >> |

|

Stainless Steel | Extremely versatile, durable, and easy to machine. | $$$$$ | View stainless steel materials >> |

|

Steel | Easy to weld, cost-efficient, and mechanically stable. | $$$$$ | View steel materials >> |

|

Copper | Easy to machine, widely available, and naturally antimicrobial. | $$$$$ | View copper materials >> |

|

Titanium | Excellent strength-to-weight properties, corrosion resistant, and biocompatible. | $$$$$ | View titanium materials >> |

|

Inconel | Corrosion-resistant and excellent precision capabilities. | $$$$$ | View inconel materials >> |

|

Brass | High durability, thermal and electrical conductivity, and easy to machine. | $$$$$ | View brass materials >> |

|

Plastic | Extremely durable materials, low cost for design testing, and wide range of applications. | $$$$$ | View plastic materials >> |

Metal CNC machining service

JawsTec’s metal CNC machining service epitomizes precision and reliability, leveraging state-of-the-art technology and expert craftsmanship to deliver exceptional results. With a focus on metals such as aluminum, steel, and titanium, we cater to a diverse array of industries, from aerospace to automotive and beyond. Whether you require prototypes, custom parts, or high-volume production runs, JawsTec’s metal CNC machining service ensures superior quality, tight tolerances, and fast turnaround times.

Plastic CNC machining service

Our plastic CNC machining service offers a comprehensive solution for customers seeking high-quality plastic components. Utilizing advanced CNC machining technology and expertise, we work with a wide range of plastic materials. Whether you need prototypes, custom parts, or production runs, our experienced machinists ensure precise fabrication to exact specifications. With a commitment to quality and efficiency, JawsTec delivers superior results with fast turnaround times, enabling clients to bring their designs to life with confidence and reliability.

FAQ’s

FAQ 1: Do you offer CAD design work?

We have an in-house CAD file designer available to hire starting at $50/hour. Email [email protected] for more information.

FAQ 2: What CNC processes do you offer?

We have CNC milling machines and CNC turning lathes.

FAQ 3: What types of finishes do you offer for CNC parts?

We can leave your parts as-machined, or andonize, powder coat, bead blast, or hard coat andonize them. You can specify the finish you want when placing your order.

FAQ 4: What CNC material types do you offer?

We can produce CNC parts in a number of metals or plastics. View our whole list of materials here.

FAQ 5: Do you offer rush production?

Rush production is available for CNC orders. You can specifiy rush production when placing your order.

FAQ 6: What process is CNC considered to be?

CNC is considered to be a subtractive process, since it works by cutting away at a block of material to form the desired object.

FAQ 7: What does CNC stand for?

CNC means Computer Numerical Control. This refers to the manner in which a computer is programmed with numbers to create the part.