Sheet Metal

Fabrication Services

Sheet metal fabrication services provide an option for producing flat or bent parts with laser cutting technology and press brakes. Sheet metal technology allows for flat or shaped metal projects, such as hinges, signs, frames, and boxes.

All Uploads are Confidential and Secure

Our sheet metal fabrication capabilities

Learn about the types of sheet metal technologies available.

Laser cutting

Laser cutting allows you to cut flat sheets of metal into desired forms or cutouts.

- Different metal materials

- Water jet, plasma, or punching cutting techniques

- Endlessly customizable

- Various applications in industries

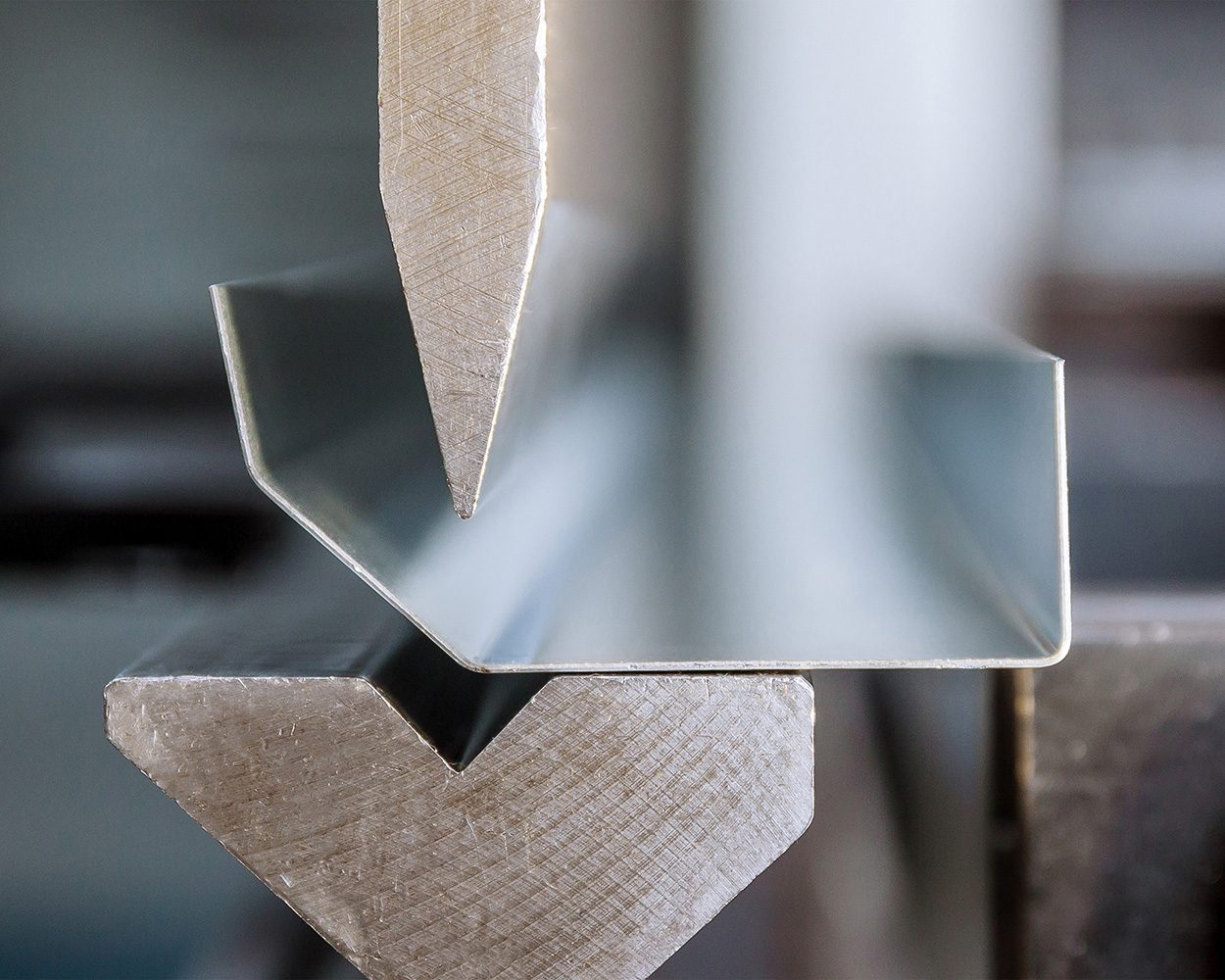

Bending

Sheet metal bending gives you the ability to shape your sheet metal project in 3D forms.

- Wider applications for projects

- Turn sheet metal into braces, hinges, and other 3D parts

- Reshaping without breaking

- More precise that traditional methods

Materials for sheet metal fabrication

We offer many different types of materials for sheet metal projects.

Aluminum |

Steel |

| Aluminum 5052 | Stainless Steel |

| Aluminum 6061 | Steel – CRS – HRPO |

| Steel – Galvanized |

Tolerances and design guidelines for sheet metal fabrication

Learn about the specifications for sheet metal project design.

Feature |

Tolerance and Guideline |

| Minimum bend | 1X sheet metal thickness |

| Minimum hole to edge distance | 2X sheet metal thickness |

| Minimum hole to hole distance | 6X sheet metal thickness |

| Minimum hole to bend edge distance | 6X sheet metal thickness |

| Minimum feature to countersink | 8X sheet metal thickness |

| Minimum countersink depth | 1X sheet metal thickness |

| Relief cuts | 1X sheet metal thickness |

| Cutting feature | +/- 0.00787″ (0.20 mm) |

| Bend angle | +/- 1.0° |

| Bend to edge | +/- 0.010″ (0.254 mm) |

Sheet metal fabrication surface finishes

Choose from a variety of post-fabrication surface finishes.

No finish

Parts are shipped as-machined, in raw condition

Anodized

Addition of thin, non-corrosive layer, smooth, pleasing surface

Powder Coated

Addition of thin paint layer, protective, available in many colors

Bead Blasted

Uniform matte finish, visual improvement, removes tool marks

Chemical Film

Chemical coating applied to protect from corrosion

JawsTec’s ordering process

Upload your files to our sheet metal fabrication quote page, be sure to specify all the details of your project. We will get back to you with a quote shortly.

Your parts will be put into production and will be professionally processed and finished. We will ship the parts according to your shipping selection at checkout.

Receive your parts at your doorstep and put them to use! Keep JawsTec in mind for your next sheet metal project.

Our other manufacturing capabilities

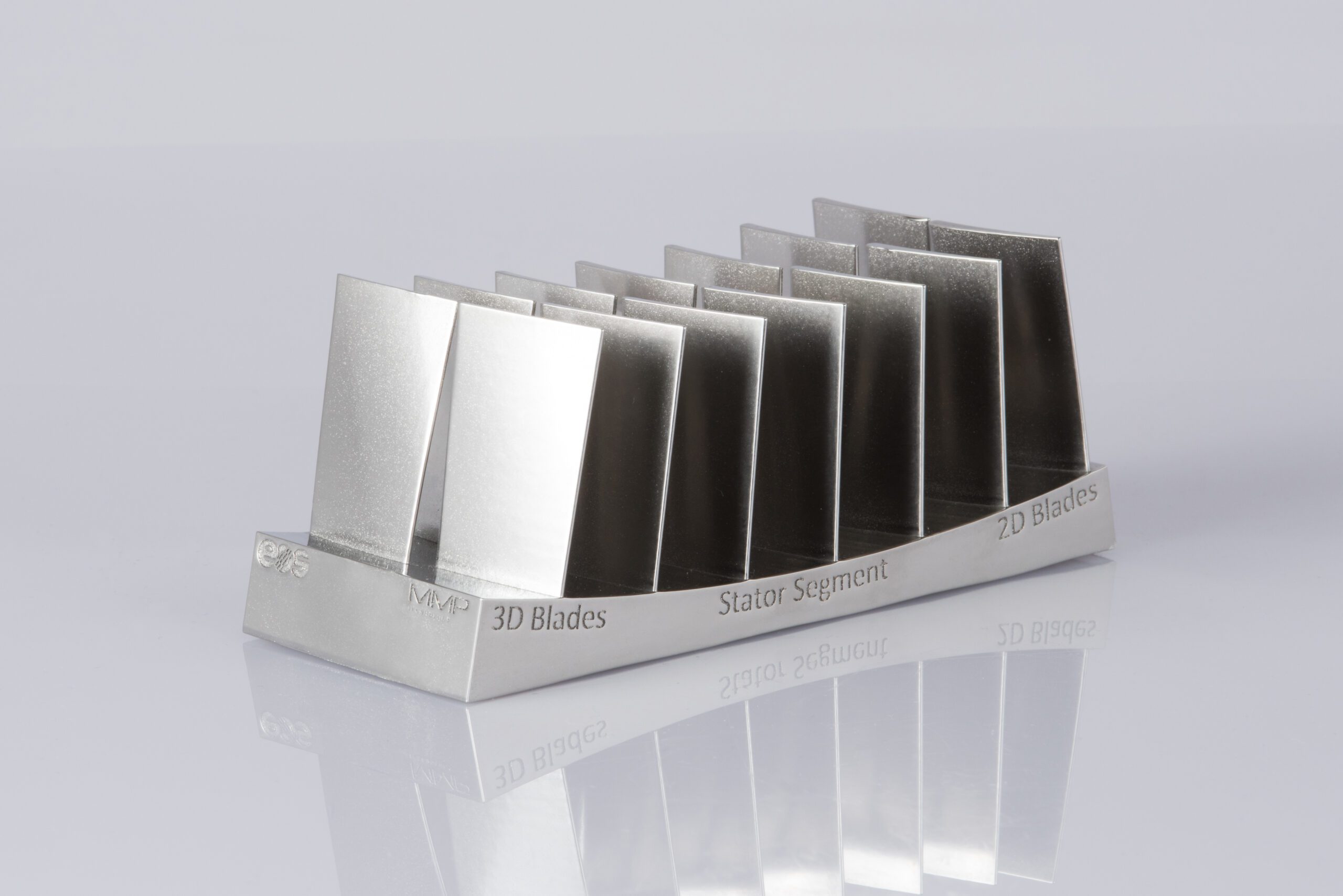

3D printing

Get your parts made easily with 3D printing. This process works by layering a polymer powder and solidifying it with a laser. Available in many colors, materials, and processes.

CNC machining

CNC machining produces parts by reading a numerical code from a file and then producing a matching part from metal or plastic material

Injection molding

A traditional manufacturing method, injection molding is best for large, production-size orders. It can be done with different materials and requires a pre-formed mold to be injected with the molten material.