HP 3D High Reusability PA 12

HP Jet Fusion 5200/4200 Series 3D Printing Solutions

In addition to HP’s flagship material, HP 3D High Reusability PA 12, HP is growing its portfolio of thermoplastics. Powders such as HP 3D High Reusability PA 12 Glass Beads and HP 3D High Reusability PA 11, deliver optimal mechanical properties. Engineered for HP Multi Jet Fusion technology, these materials test the limits of functional part creation, optimizing cost and part quality, while also delivering high and, in many cases, industry-leading reusability at a low cost per part.

Produce strong, functional, detailed complex parts

- Robust thermoplastic produces high-density parts with balanced property profiles and strong structures.

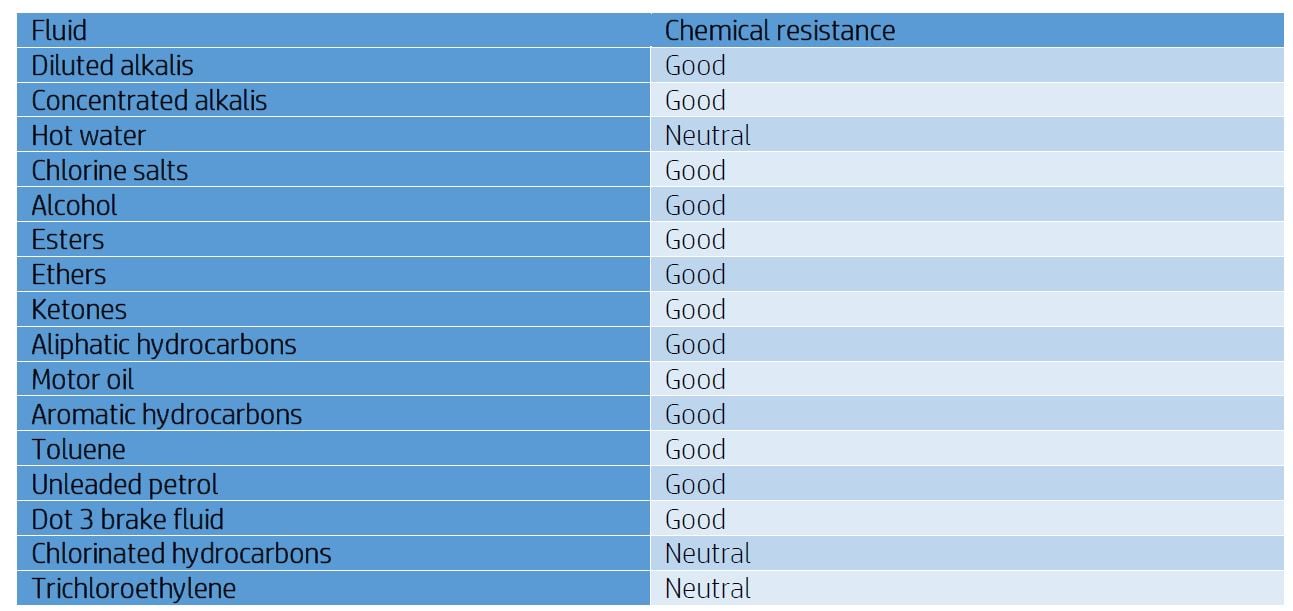

- Provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies.

- Ideal for complex assemblies, housings, enclosures, and watertight applications.

- Biocompatibility certifications—meets USP Class I-VI and US FDA guidance for Intact Skin Surface Devices.

Engineered for HP Multi Jet Fusion technology

- Designed for the production of functional parts across a variety of industries.

- Provides the best balance between performance and reusability.

- Achieves watertight properties without any additional post-processing.

- Engineered to produce final parts and functional prototypes with fine detail and dimensional accuracy.

Quality at the lowest cost per part

- Achieve the lowest cost per part1 and reduce your total cost of ownership.

- Minimize waste—reuse surplus powder batch after batch and get functional parts, no throwing away anymore.

- Get consistent performance while achieving 80% surplus powder reusability.

- Optimize cost and part quality—cost-efficient material with industry-leading surplus powder reusability.

MJF PA12 has a high chemical resistance to a wide variety of commonly-used fluids in the industry.

** Information provided by HP 3D Printing.