3D printing materials

Resin 3D printing service

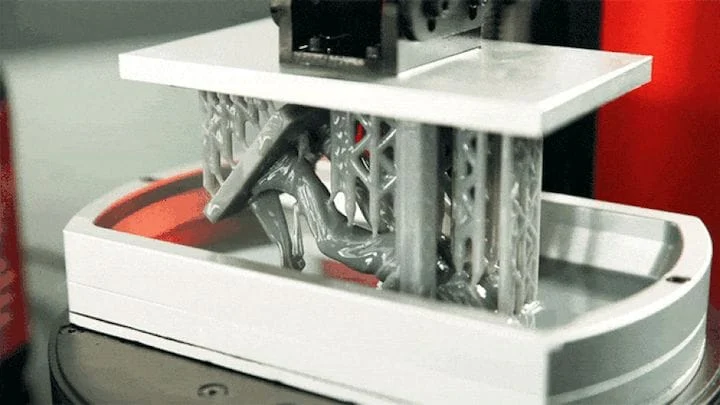

3D printing with resin involves the stereolithography process. This manufacturing method works by using a laser to solidify a liquid polymer into a hard plastic form.

SLA Resin Materials

SLA is best used for complex parts that require high-accuracy and a smooth finish.

Description

| Applications | Resin printing is best for mechanical aerospace or automotive parts, functional prototypes, digital electronics parts, and watertight parts. |

| Strengths |

|

| Weaknesses |

|

Characteristics

| Price | $ $ $ $ $ |

| Lead Time | 20+ business days |

| Wall Thickness | 1 mm |

| Tolerance | 200µm |

| Max part size | 1380mm x 680mm x 480mm |

| Layer height | 50µm – 200µm |

Available SLA materials

SLA High Temp TS

SLA High Temp TS has increased strength and durability characteristics. It is great for automotive projects with isotropic mechanical properties. It has an industrial, dark blue default color, making it perfect for mechanical applications. It is also highly applicable in aerospace fields, for parts like display panels and dashboards.

SLA Imagine Black

Similar to engineering plastics, SLA Imagine Black has stable performance, dimensional stability, and is chemically resistant. It also saves on dying costs, as it comes in a pure black default color. A small drawback is that it is slightly weaker than nylon.

SLA Proto Plus

Proto Plus is an accurate and durable material. It is suitable for prototyping needs, although may not hold up as well as other materials. It comes in a default white that can appear slightly yellowish, but these parts can be dyed to other colors. This material is an excellent option for consumer medical parts.

SLA Smooth GP

This white material is water and moisture proof, and has high cost performance. It is known to turn yellowish and become brittle when left in sunlight. For products that need to be more UV resistant, we suggest nylon or another material. Smooth GP is great for digital electronic modifications.

SLA Tough Plus

SLA Tough Plus is a great option for prototyping and test parts, but is not suitable for end use pieces because of its impressionable nature. Additionally, it tends to fade to yellow with time. This material can be painted or dyed after production. Parts from SLA Tough Plus will have outstanding detail.

SLA Tough Resin Green

This material has excellent heat resistance and dimensional stability. It is also extremely stable and durable. The printing speed for Tough Resin Green is very quick and efficient. One limitation is that this material has a default color of light green/yellow. It can be modified for end use products.

SLA Transparent Plus

This material is mostly clear when printed. It is an excellent option for projects like wind tunnels, liquid containers, and sturdy concept models. One drawback with Transparent Plus is that it may result in small air bubbles in the surface of the print. However, these can sometimes be fixed with printer adjustments.

SLA WaterTight Proto

SLA WaterTight Proto has excellent waterproof abilities. It is also very resistant and durable. It comes in a default color of whitish yellow but can be colored. It is good for use in batch runs and end use pieces, from medical models to household parts. It is also an option for interior car parts.

FAQ’s

FAQ 1: Will you share my files and designs on social media or with other people?

No, we never share files or designs without the permission of you, the customer.

FAQ 2: Do you offer scanning off another 3D model?

No, we do not offer this service.

FAQ 3: What types of finishes do you offer?

We offer raw, tumbled, polished, and vapor polished finishes on all our parts except for SLA resin parts.

FAQ 4: Does tumbling, polishing, or vapor polishing affect the dimensions of my parts?

Tumbling, polishing, or vapor polishing finishes may affect the final dimensions of your parts by 0.05mm.

FAQ 5: Do you offer rush production?

Rush production is available for MJF PA12, SLS PA12, and SLS PA2200. However, you must have your orders in by 2:00 MST in order to start printing the same day. If you order comes in after 2:00 MST, your rush production order will be delayed by one business day. You can select rush production on our quote page.

FAQ 6: What is your most flexible material?

Our TPU with a shore hardness of 86A is the most flexible material we have.

FAQ 7: What type of files can you print off of?

We can print off almost any CAD file type. We prefer .STL files.