EOS SLS PA 2200

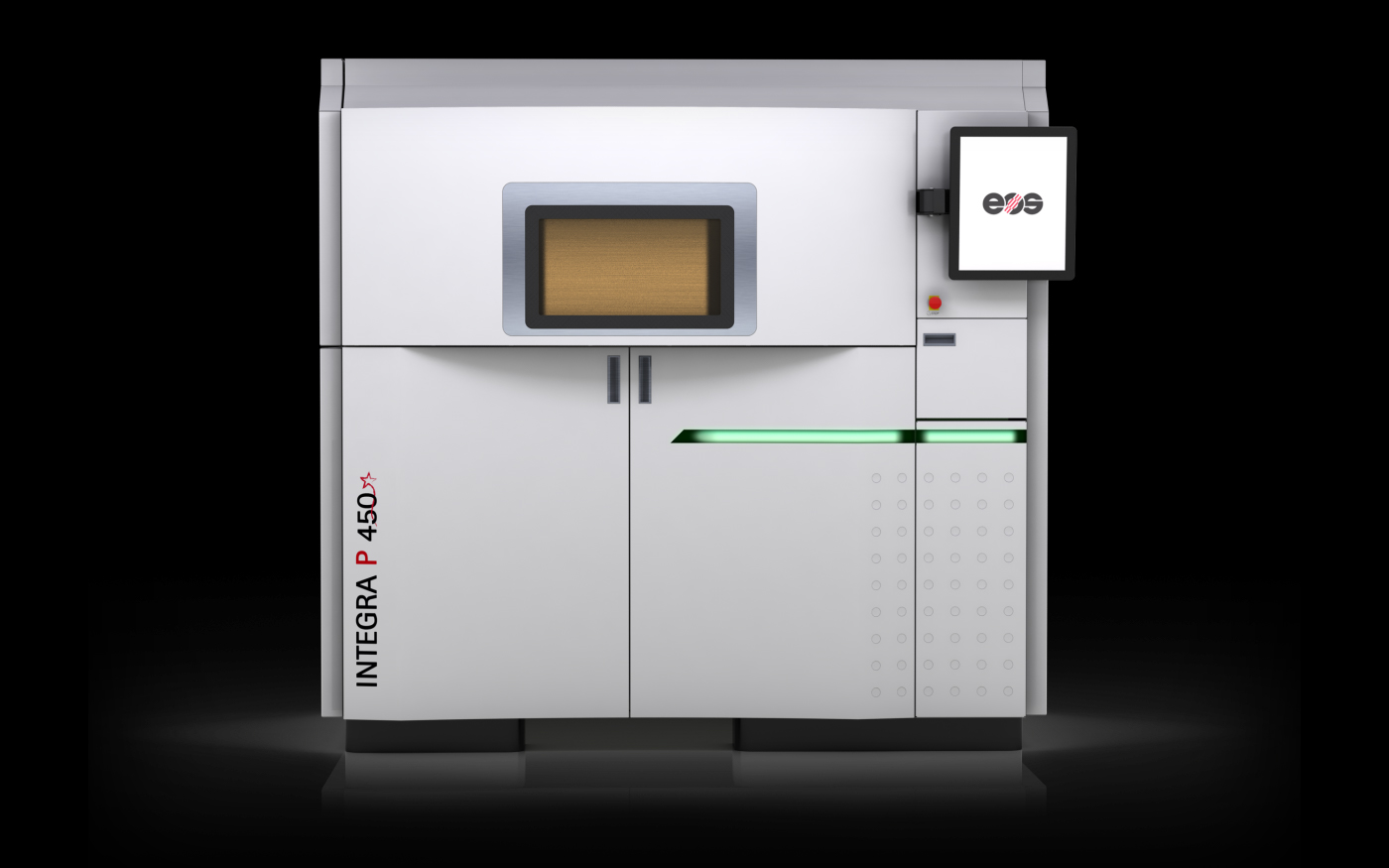

EOS P396 and EOS P770 3D Printing Solutions

White polyamide 12 powder, also known as nylon, is the most tested material for additive manufacturing on the market. Parts made from nylon are robust, stable for long periods of time, chemically resistant and extremely versatile. EOS materials based on polyamide 12 are a high-performance alternative to plastics like ABS or PA6 that have proven their value in injection molding. The additively manufactured end products are just as strong, flexible and durable as molded parts.

This whitish fine powder PA 2200 on the basis of polyamide 12 serves with its very well-balanced property profile a wide variety of applications. Laser-sintered parts made from PA 2200 possess excellent material properties such as below:

- High Strength and Stiffness

- Good Chemical Resistance

- Excellent Long-Term Constant Behaviour

- High Selectivity and Detail Resolutions

- Various Finishing Possibilities (e.g. Metallisation, stove enamelling, vibratory grinding, tub colouring, bonding, powder coating, flocking.)

- Bio-Compatible According to EN ISO 10993-1 and USP/Level VI/121 °C

- Approved for Food Contact in Compliance with the EU Plastics Directive 2002/72/EC (exception: high alcoholic foodstuff)

120 microns layer thickness:

The Advantage of the Balance paramet6er set is equilibrium. The layer thickness of 120 microns offers a perfect balance between production costs, mechanical properties, surface quality, and accuracy. It is, therefore, suitable for parts with varying geometries, dimensions, and requirements.

Mechanical Properties |

Value |

Unit |

Test Standard |

| Flexural Modulus (23 ° C) | 1500 | MPa | ISO 178 |

| Izod Impact Notched (23 °C) | 4.4 | kJ/m | ISO 180/1A |

| Shore D Hardness (15s) | 75 | — | ISO 868 |

The properties of parts manufactured using additive manufacturing technology (e.g. laser sintering, stereolithography, Fused Deposition Modelling, 3D Printing) are, due to their layer-by-layer production, to some extent direction-dependent. This has to be considered when designing the part and defining the build orientation.

3D Data |

Value |

Unit |

Test Standard |

| Tensile Modulus (X Direction) | 1650 | MPa | ISO 527-1/-2 |

| Tensile Modulus (Y Direction) | 1650 | MPa | ISO 527-1/-2 |

| Tensile Modulus (Z Direction) | 1650 | MPa | ISO 527-1/-2 |

| Tensile Strength (X Direction) | 48 | MPa | ISO 527-1/-2 |

| Tensile Strength (Y Direction) | 48 | MPa | ISO 527-1/-2 |

| Tensile Strength (Z Direction) | 42 | MPa | ISO 527-1/-2 |

| Strain at Break (X Direction) | 18 | % | ISO 527-1/-2 |

| Strain at Break (Y Direction) | 18 | % | ISO 527-1/-2 |

| Strain at Break (Z Direction) | 4 | % | ISO 527-1/-2 |

| Charpy Impact Strength (+23 °C, X Direction) (+23°C) | 53 | kJ/m2 | ISO 179/1eU |

| Charpy Notched Impact Strength (+23 °C, X Direction) (+23°C) | 48 | kJ/m2 | ISO 179/1eA |

** Information provided by EOS 3D