EOS TPU 1301

EOS Flexible Polymer Material

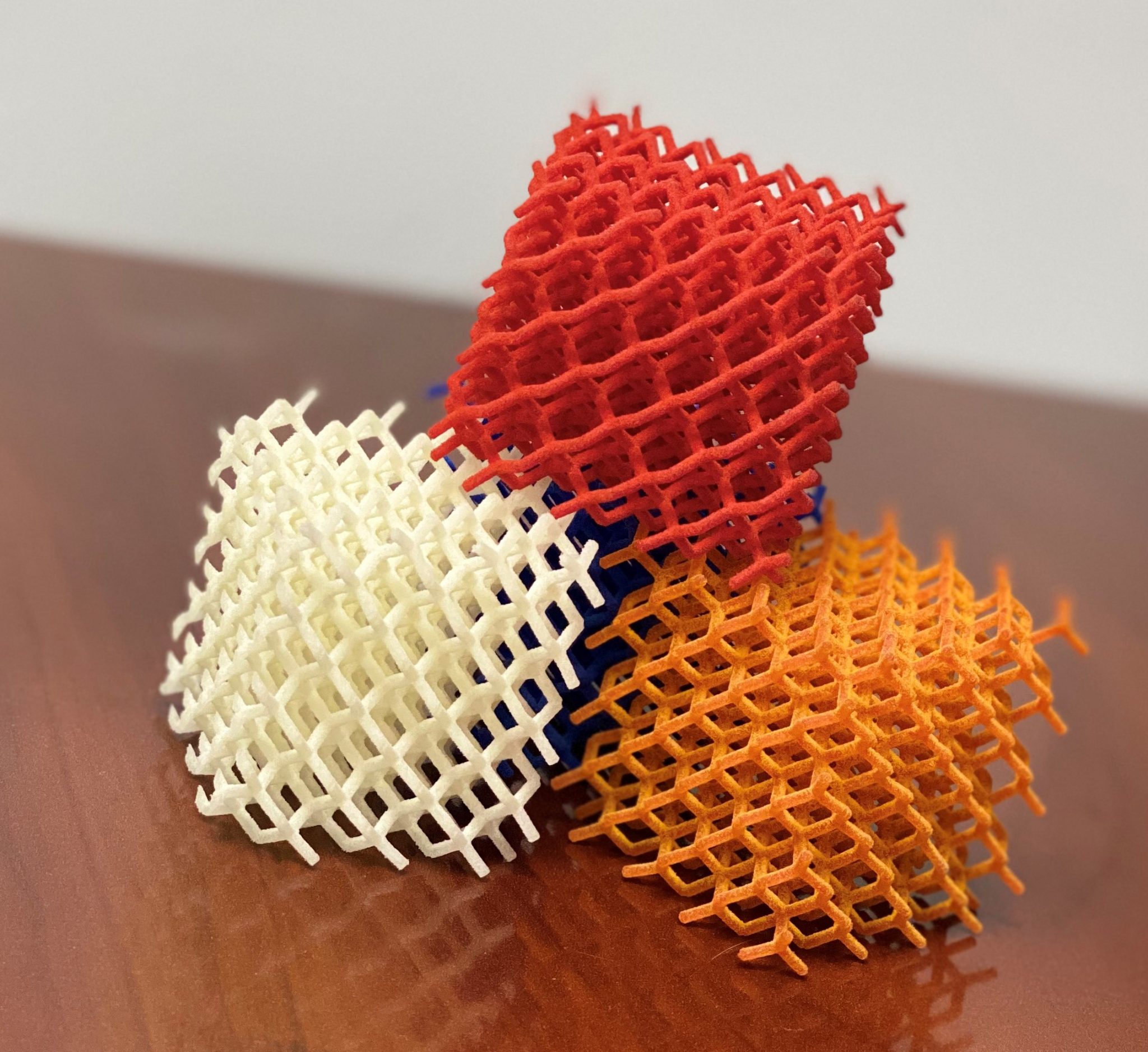

The part properties such as flexibility and level of damping of this TPU can be adjusted via structural design with lattice structure, or by adapting the process parameters.

Main Characteristics

- Great Resilience

- Good Hydrolysis Resistance

- High UV-Stability

- Very Good Shock Absorption

- Shore Hardness 86A

- Low Refresh Rate

Typical Applications

- Footwear and Lifestyle Parts that Demand Elastomeric Properties, e.g. Handles, Shoe Soles

- Automotive and Industry Parts, e.g. Tubes, Bellows, Seals, Gaskets

- Protective Sports Gear, e.g. Helmet Cushioning

- Applications Usually Made from Foam Can Be Replaced by Lattice Structures in EOS TPU 1301

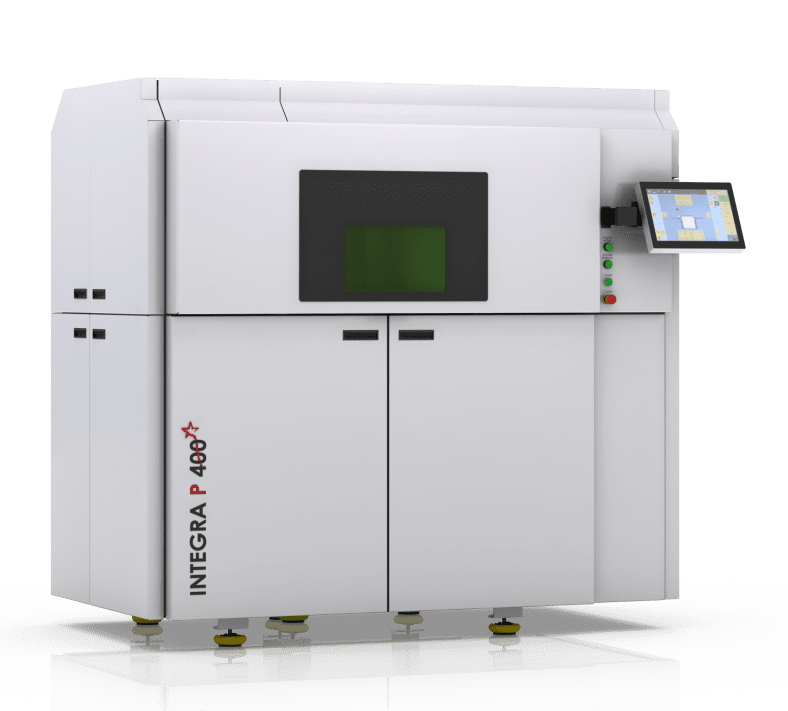

** Information provided by EOS 3D Printing.