Additive manufacturing has held its own in multiple industries for decades. But what is additive manufacturing? What types of additive manufacturing are out there?

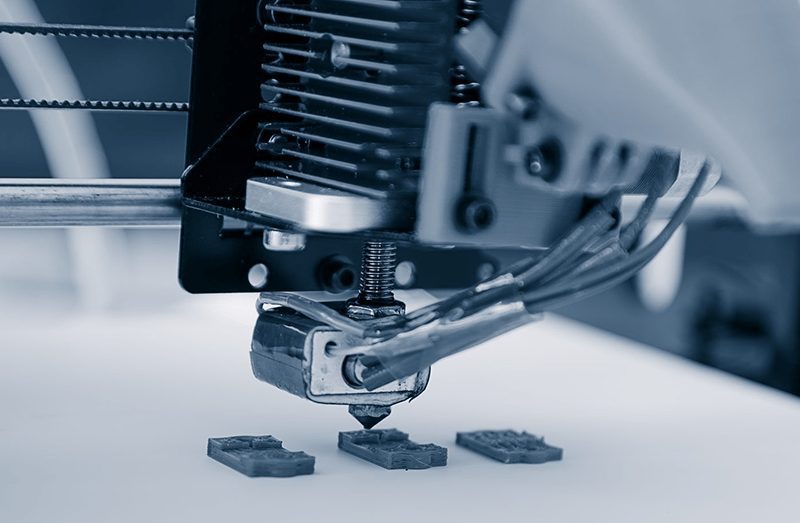

Additive manufacturing is what it says: it is a form of manufacturing where material is added on to create an object, rather than taken away like you see in subtractive techniques like machining. This type of manufacturing comes with a number of advantages for many products, allowing for custom design to a degree and at a cost that is not often seen with subtractive manufacturing methods.

What are the types of additive manufacturing?

Most forms of additive can be classed as forms of 3D printing, though their methods for printing and fusing materials together varies. Many researchers are in the process of developing new methods that work better with different materials, which will open up new frontiers for additive manufacturing.

Some of the most common types of additive manufacturing are:

- Inkjet- What most people think of when they think of 3D printing. This method applies powders or liquids in thin layers to steadily build up the object.

- Electron beam melting- Here, an electron beam melts layers of powder into the desired object in a vacuum. Magnetic fields are used to direct the beam. It is often used to make metal parts that are similar to heat-treated objects, with little residual stress.

- Selective Laser Sintering (SLS)- Similar to electron beam melting, SLs uses a high-heat laser to melt powder into a selected shape layer by layer. It is also used often for metals, but also sees a lot of use for nylon and plastic materials as well. The metal parts are not as strong as those produced by electron beam melting, but this method is more economical and, because the laser is not as hot, can sinter a wider variety of materials.

- Aerosol jetting- Relatively new, this method is used to create very fine details using an aerosol spray of material. It has seen use at NASA for creating very small custom electronic components.

As you can see, additive manufacturing can cover most manufacturing bases, from simple objects to fine detail. When engineers start thinking in terms of creating something that is built up, rather than manchiend out, it changes how they think of design= as well as how they think of the tools to make it.

At Jawstec, we are experts in additive manufacturing. We understand the ins and outs of additive manufacturing technology. Our expert team is on hand to help you walk your project from its earliest design phase as a computer file to printing it using the ideal additive manufacturing techniques. Contact us today for a quote to help your project enter the additive manufacturing world.

0 Comments