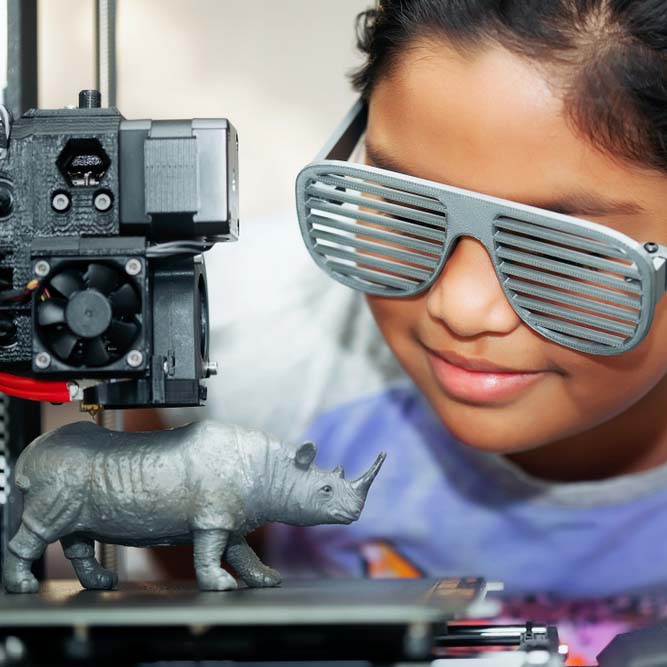

Introduction to FDM 3D Printing

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, revolutionizing manufacturing, prototyping, and even hobbyist projects. Understanding the intricacies of FDM technology is crucial for consistently achieving high-quality prints.

Understanding FDM Technology

What is FDM?

FDM is an additive manufacturing process where a thermoplastic filament is heated and extruded through a nozzle layer by layer to create a three-dimensional object.

How does FDM work?

The FDM printer receives digital instructions from a computer-aided design (CAD) file. The filament is fed into the printer, melted in the extruder, and deposited onto the build plate in precise layers, solidifying upon cooling.

Common Issues in FDM 3D Printing

FDM printing can encounter several challenges that hinder print quality and success.

Filament Quality and Consistency

The quality and consistency of the filament are paramount to successful prints. Inconsistent diameter, moisture absorption, or impurities can lead to print defects.

Nozzle Clogging

Nozzle clogs occur when debris or melted filament obstructs the nozzle opening, disrupting filament flow and causing print failures.

Warping and Bed Adhesion Problems

Warping happens when printed layers cool at different rates, causing edges to lift from the build plate. Poor bed adhesion exacerbates this issue, leading to warped prints or detachment from the bed mid-print.

Layer Misalignment

Layer misalignment results in uneven or shifted layers, causing structural weaknesses and aesthetic flaws in prints.

Print Speed and Temperature Settings

Incorrect print speed and temperature settings can lead to under-extrusion, stringing, or overheating issues, affecting print quality.

Environmental Factors

Environmental conditions such as temperature and humidity can impact filament behavior and print outcomes, requiring adjustments for optimal results.

Identifying Filament Quality and Consistency Issues

Importance of Filament Quality

High-quality filament ensures smooth extrusion and consistent prints. Evaluate filament diameter, material purity, and manufacturer reputation before printing.

Signs of Poor Filament Quality

Look out for irregular filament diameter, discoloration, brittleness, or excessive moisture, which indicates poor-quality filament.

Solutions to Filament Quality Issues

Invest in reputable brands, store filament properly in airtight containers with desiccants, and perform regular quality checks before printing.

Preventing and Resolving Nozzle Clogging

Causes of Nozzle Clogging

Nozzle clogs can occur due to debris buildup, poor filament quality, or improper temperature settings.

Steps to Prevent Nozzle Clogging

Regularly clean the nozzle, use a quality filament, and ensure proper temperature and retraction settings to minimize clogging risks.

Clearing Nozzle Clogs

Utilize cleaning tools, cold pulls, or nozzle replacement to clear stubborn clogs and restore filament flow.

Addressing Warping and Bed Adhesion Problems

Understanding Warping

Warping results from uneven cooling of printed layers. Minimize temperature differentials and use appropriate bed adhesion methods to prevent warping.

Improving Bed Adhesion

Enhance bed adhesion with proper leveling, surface treatment, or adhesion aids like glue sticks or adhesive sprays.

Tips for Minimizing Warping

Optimize print orientation, adjust temperature and cooling settings, and consider using enclosed print chambers for better temperature control.

Troubleshooting Layer Misalignment

Causes of Layer Misalignment

Layer misalignment can stem from mechanical issues, software glitches, or improper printer calibration.

Adjustments to Correct Layer Misalignment

Check printer mechanics, update firmware, and recalibrate printer settings to align layers accurately.

Optimizing Print Speed and Temperature Settings

Impact of Speed and Temperature

Print speed and temperature directly influence print quality, strength, and surface finish.

Finding the Right Settings

Experiment with different speed and temperature combinations to find the optimal balance for your specific filament and print requirements.

Experimentation and Calibration

Regularly calibrate your printer and document settings, and track print outcomes to refine your printing parameters.

Managing Environmental Factors

Temperature and Humidity Considerations

Control printing environment temperature and humidity levels to minimize filament moisture absorption and printing complications.

Enclosure Solutions

Consider enclosing your printer to maintain stable environmental conditions, especially for printing materials sensitive to temperature and humidity fluctuations.

Conclusion

In conclusion, FDM 3D printing offers incredible opportunities for creativity and innovation, but success relies on effectively understanding and addressing common challenges. By implementing proper filament management, nozzle maintenance, print settings optimization, and environmental control measures, enthusiasts and professionals can achieve consistent, high-quality prints with FDM technology.

FAQs (Frequently Asked Questions)

- What are the leading causes of nozzle clogging?

- Nozzle clogging can occur due to debris buildup, poor filament quality, or improper temperature settings.

- How can I prevent warping in my prints?

- Minimize warping by optimizing print orientation, adjusting temperature and cooling settings, and enhancing bed adhesion.

- Why is filament quality important in FDM printing?

- High-quality filament ensures smooth extrusion and consistent prints, minimizing the risk of print defects and failures.

- What should I do if my layers are misaligned?

- Troubleshoot layer misalignment by checking printer mechanics, updating firmware, and recalibrating printer settings.

- How can I optimize print speed and temperature settings?

- Experiment with different speed and temperature combinations to find the optimal balance for your specific filament and print requirements.

- Are there any environmental factors I should consider for FDM printing?

- Control temperature and humidity levels to minimize filament moisture absorption and printing complications, especially for temperature-sensitive materials.

- What are some signs of poor filament quality?

- Look out for irregular filament diameter, discoloration, brittleness, or excessive moisture, which indicates poor-quality filament.

- What steps can I take to clear nozzle clogs?

- Utilize cleaning tools, cold pulls, or nozzle replacement to clear stubborn clogs and restore filament flow.

0 Comments