Polypropylene Multi Jet Fusion

Genuine PP

Now available the commonly used PP base material in 3D Printing. Accelerate your design process using the same prototyping base material as the final part.

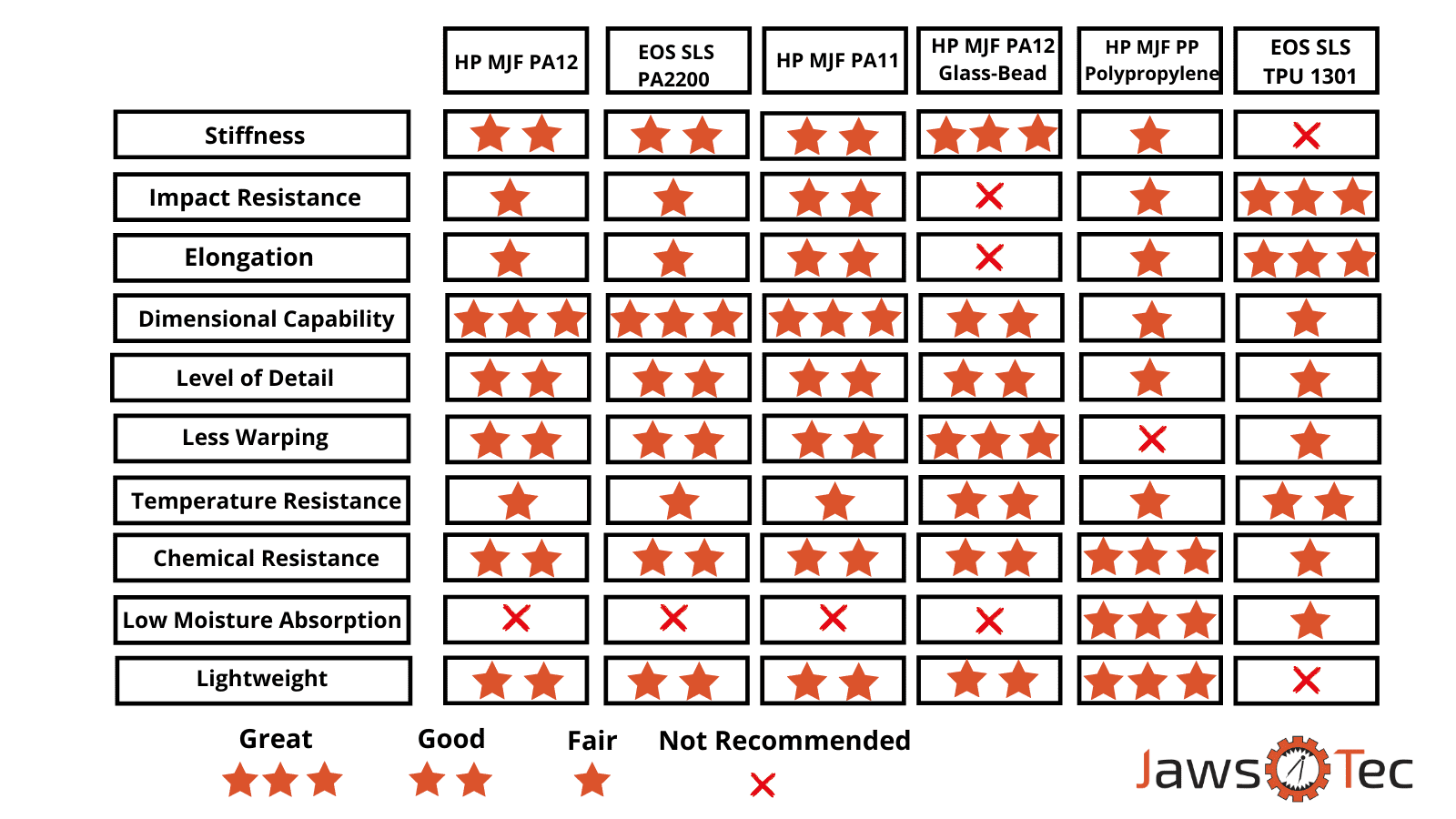

Material Properties

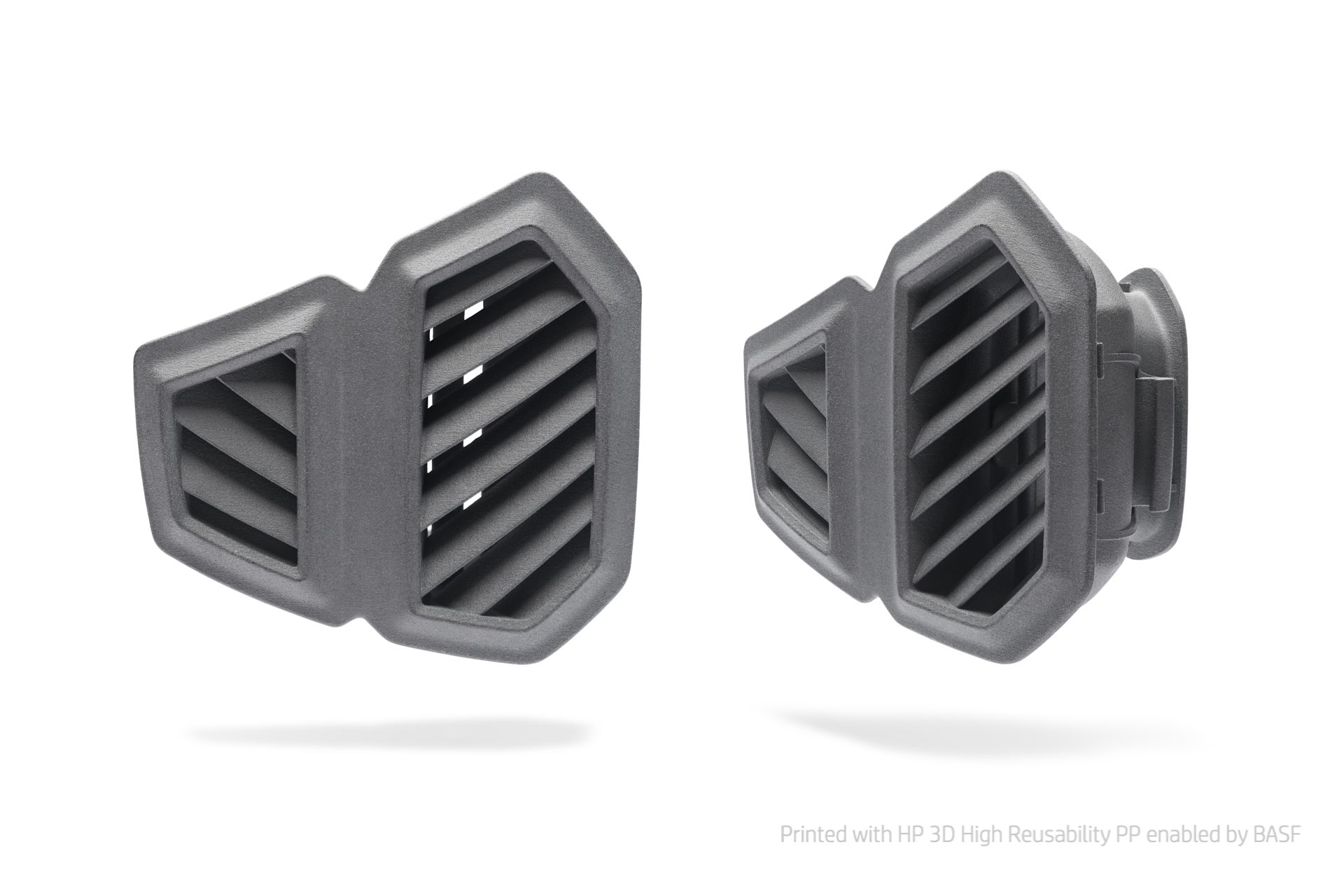

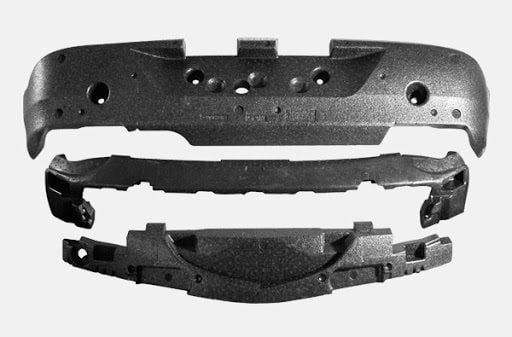

Polypropylene is a versatile material ideal for a wide range of automotive, consumer, industrial, and medical applications. The new HP 3D High Reusability PP enabled by BASF provides customers with a genuine new additive manufacturing material offering the same properties as commonly used PPs in injection molding, which has proven to have nearly unlimited use. With its excellent chemical resistance, low moisture absorption, and long-term durability, PP is ideal for piping, fluid systems, and containers. For example, automakers will be able to use the same PP for prototyping and production of final parts found in vehicles’ interior, exterior, and under-the-hood.

Material Description: Polypropylene is a different material than polyamides

- PP retains more heat than polyamides (has lower thermal conductivity and diffusivity).

- PP takes longer to cool than polyamides and must cool down at room temperature to avoid part deformation.

- PP has a narrow processing window, which means that there’s no much printing space between melting and crystallization.

- PP crystallizes more than PA12 and PA11 and has more crystal phases, which causes more shrinkage and makes PP more susceptible to dimensional variances.

- The printing accuracy is affecting because of the way the material crystallizes. Tolerance for MJF 3D printed PP is as follows

(X,Y): +/- 0.500 MM OR > 100MM +/- 0.7%

(Z): +/- 0.800 MM OR > 100 MM +/- 1.1%

Functional Properties

- Excellent chemical resistance.

- Great surface finish.

- Welding capabilities with PP IM.

- Low moisture absorption

Material Performance: Welding Capabilities Successfully tested several welding technologies wth HP PP parts together with injection-molded PP.

- Heat Staking

- Hot Staples

- Spin Welding

- Infraweld

- Spot Welding

- Ultrasonic Welding

- Hot Plate

- Soldering Iron

- Vibration Welding

- Laser Welding

Material Performance: Chemical Resistance

Sodium Hydroxide, 1M

- Very common base

- PP material knows to be somewhat susceptible to degradation with NaOH in general

- Represents ‘caustic’ chemical, sodium hydroxide used in soap-making process

6WT% H2SO4

- Very common acid

- H2SO4 used by automotive customers to emulate battery acid

Hydrogen Peroxide (OTC, -3% Concentration)

- PP material is known to be somewhat susceptible to oxidative degradation. Will demonstrate robustness

Water

- Internal control

- No reactivity expected

Ethanol (.90%)

- Very common solvent that applies across multiple applications like windshield washer fluids, alcohols for medical applications, etc.

Industry Opportunites

Industrial:

- Machinery parts

- Tubes

- Piping

- Fluid System Reservoirs

Automotive:

- Interior parts

- Welded parts

- Fluid systems

- HVAC

- Functional

- Prototyping

Consumer Goods:

- Household appliances

- Cosmetics applications

Medical:

- Medical devices

- Orthodontics

Which HP Material is BEST for my application?