In today’s dynamic market landscape, the ability to prototype and adapt quickly is essential for staying competitive. Additive manufacturing, commonly known as 3D printing, has emerged as a game-changer. By enabling rapid prototyping and iteration, additive manufacturing facilitates faster product development cycles, allowing businesses to respond to market demands and consumer feedback swiftly. This introduction sets the stage for exploring how additive manufacturing revolutionizes product development by accelerating innovation and enhancing agility in adapting to evolving market trends.

Importance of Product Development

Product development is the lifeblood of any business, driving innovation and market competitiveness. It involves transforming ideas into tangible products that meet customer needs and demands.

Role of 3D Printing in Product Development

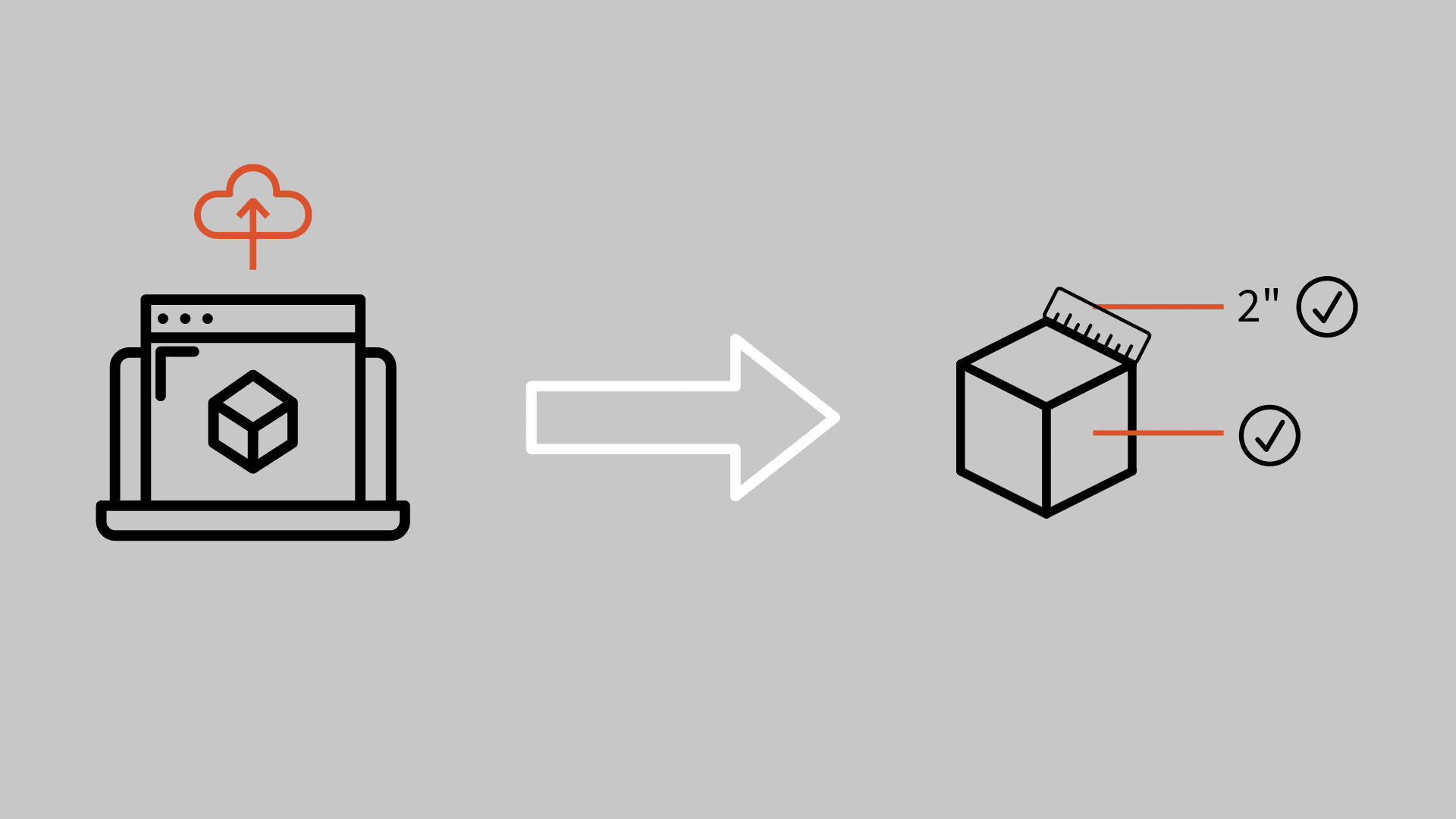

3D printing plays a crucial role in expediting the product development process. Its capabilities extend beyond traditional manufacturing methods, offering advantages such as rapid prototyping, customization, and cost-effectiveness.

Steps Involved in Product Development with 3D Printing

The product development process with 3D printing encompasses several stages, from the initial design phase to the final product refinement. Each step involves meticulous planning and execution to ensure a successful outcome.

Advantages of Using 3D Printing Services in Product Development

Utilizing 3D printing services offers numerous benefits for product development, including accelerated time to market, reduced costs, enhanced design flexibility, and improved product quality. With high-quality customer service, you can understand your product’s restrictions before even printing. This allows for quicker implementation of fixes and adjustments.

Challenges and Limitations

Despite its advantages, 3D printing poses challenges, such as material limitations, post-processing requirements, and scalability issues for mass production. Small to medium production is perfect, but large manufacturing jobs will require redesigning for injection molding or other potential changes.

Future Trends and Innovations

The future of product development with 3D printing holds promising opportunities, with advancements in materials, printing techniques, and automation set to revolutionize manufacturing processes. Development help with a community also will become a process. The Skool Community Innovation Gateway is one such project that JawsTec’s CEO has started to help understand critical frustrations and build a better rapport with individuals in the product development market.

Conclusion

In conclusion, 3D printing services have become indispensable tools for product development, offering unparalleled speed, flexibility, and cost-efficiency. Embracing this technology enables businesses to stay ahead in today’s competitive market landscape.

FAQs

- What types of products can be developed using 3D printing?

- 3D printing can be used to develop a wide range of products, including prototypes, customized parts, medical implants, and even food items.

- How does 3D printing reduce costs in product development?

- By eliminating the need for expensive molds and tooling, 3D printing significantly reduces upfront costs in product development.

- What are the limitations of 3D printing in product development?

- Some limitations include material restrictions, surface finish limitations, and challenges with scalability for mass production.

- Is 3D printing suitable for all industries?

- While 3D printing has applications across various industries, its suitability depends on material requirements, production volume, and regulatory considerations.

- What are the future trends in 3D printing for product development?

- Future trends include advancements in multi-material printing, bioprinting for tissue engineering, and the integration of artificial intelligence for design optimization.

0 Comments