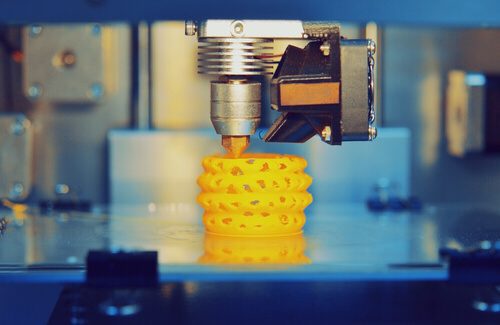

3D printing is a revolutionary technology that has drastically changed the way professionals and hobbyists alike create physical objects. From custom prototyping to producing small-batch products, 3D printers are becoming increasingly popular. Whether you’re a professional designer or a small business owner, investing in the right 3D printer can help you save time and money. But with so many options available, it can be difficult to decide which industrial 3D printer is right for you. This comprehensive guide will help you find the best 3D printer for your needs by providing an overview of the top 3D printers currently available. From desktop to industrial-grade machines, you’ll learn what features to look for and how to compare the different options on the market. So, if you’re looking for the best 3D printer for professionals, this guide has you covered.

Overview of 3D Printer Types

When shopping for a 3D printer, it’s important to understand the different types of machines available. This will help you identify the features you’re looking for and determine which printer is right for you. There are four main types of 3D printers: – FDM/FFF: Fused Filament Fabrication (FFF) is the most common type of 3D printing. It works by melting a spool of plastic filament and extruding it through a nozzle to create a 3D model. FDM (Fused Deposition Modeling) is a variation of FFF where the filament is deposited as a continuous strand instead of in individual lines. While FDM is more expensive, it’s also more accurate and stronger than FFF. FFF is best suited for small-scale production and short-run prototypes. While FDM is more cost-effective for higher-volume products. – SLA: Stereolithography uses a photosensitive resin that hardens when it’s exposed to a laser. This type of 3D printer is ideal for creating prototypes and small-batch products, but it’s generally not recommended for production. – SLS: Selective Laser Sintering uses a laser to fuse particles together to create a 3D model. SLS is best for producing high-end prototypes or end-use parts. – MJF: Multi Jet Fusion uses an inkjet process that was developed by HP. They know what they are doing when it comes to ink printing and they have developed a high-quality industrial machine that costs roughly $300k or more but produces some very beautiful parts. These are best for end-use and production runs. 3D printing services are the best location to get these parts without investing in the printer, post-processing, and finishing options that come with the machine.

What to Look for When Choosing a 3D Printer

While all 3D printers can create an object from a digital file, not all of them are created equal. Here are some things to keep in mind when shopping for a 3D printer to help you select the best machine for your needs. – Build Volume – The build volume is the maximum size your 3D printer can print. This will determine the size of your models and how much they cost to produce. If you’re printing large models, you may want to look for a machine with a larger build volume. – Speed – 3D printing is a slow process, but it varies depending on the type of 3D printer you use. You may want to prioritize speed if you’re regularly in need of urgent prototypes. – Technology – While FDM and SLA are the most common types of 3D printing, there are other technologies available. You may want to compare SLS, MJG, and other lesser-known 3D printing methods to see which one is best for your needs.

Popular 3D Printer Technologies

As you researched the various 3D printer types, you may have come across some unfamiliar terms such as photopolymer, resin, and CO2 Laser. If you’re not sure what these terms mean or how they differ, here’s a quick overview of the most common 3D printing technologies. – Photopolymer – Photopolymer-based printers create objects from a liquid resin that’s hardened by a UV light source. This technology is best for prototyping and short-run production. – Resin – Resin-based printers use a spool of resin that is hardened with a laser and then deposited onto a build platform. Resin-based 3D printers are best for prototyping and short-run production. – CO2 Laser – CO2 laser-based printers fuse particles together to create a 3D model. This technology is best for high-end prototyping and single-use parts. This process is used in SLS printing and that is why it can have high-quality parts while being accurate and functional. – Inkjet – Inkjet printers use a combination of fusing and detailing agents to provide the highest quality parts in surface finish, density, strength, and overall accuracy.

Industrial 3D Printers

Industrial 3D printers are best suited for large-scale production, short-run, and prototype applications. These machines are more expensive than their desktop counterparts, but the high upfront cost can be worth the investment. Industrial 3D printers often include advanced features such as network connectivity to streamline the design and production process. Additionally, they’re built to last with larger build volumes that allow you to produce more parts in less time. If you’re in the market for an industrial 3D printer, you may also want to consider purchasing used equipment. While buying used often comes with a higher upfront cost, it can save you money in the long run. It’s also a great option for designers on a budget. You’ll just need to make sure the equipment is in good condition and comes with a warranty.

Comparing 3D Printers

Once you’ve identified the features you’re looking for in a 3D printer and narrowed down your options, it’s time to compare the different models to help you make an informed decision. Remember, sometimes it’s a great idea to let more involved individuals print your product and ship it to you like an Amazon-style of operation. Most 3D printing services have a drag-and-drop engine for quoting out projects for prototyping or production work. Here are some factors to consider as you compare 3D printers. – Price – Price is often the deciding factor when it comes to purchasing new equipment. Before you make a final decision, consider shopping around to find the best deal on the right 3D printer for your needs. – Build Volume – The build volume is the maximum size your 3D printer can print. This will determine the size of your models and how much they cost to produce. – Technology – You may want to compare different 3D printing technologies to see which one is best for your needs. – Speed – If you’re regularly in need of urgent prototypes, you may want to prioritize speed.

Conclusion

Choosing the right 3D printer can be a daunting task. With so many models on the market, it can be difficult to decide which one is right for you. To start, you’ll want to identify the features you’re looking for and determine which machine is best for your needs. Once you’ve narrowed down your options, compare the different models to help you make a final decision. With the right machine, it’s possible to save time and money while producing high-quality parts and prototypes. Now that you know what to look for, finding the best 3D printer for your needs is easier than ever before.

0 Comments