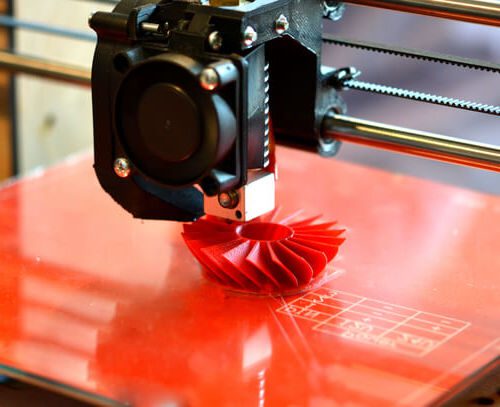

For a lot of people, 3D printing seems like a novelty. However, it has started to see a lot of serious, real-world use, especially in major industries such as aerospace and auto. In fact, 3D printing is starting to make an impact in Formula 1 racing.

3D printed car parts have many advantages that benefit Formula 1 especially. The customizability means that a part can be printed on demand. Rapid prototyping with designs and material is easy to do, especially when compared to other manufacturing processes.

Formula 1 has often been an early adopter of new technology. Fast, light, stronger parts are the goal, and 3D printed car parts are key. Renault F1 purchased and began to use its first 3D printer in 1998 to print car parts. Currently, the McLaren Formula 1 Racing Team is partnered with 3D printing firm Stratsys. Likewise, Renault is working with 3D Systems and Williams Formula One works with EOS.

3D printed car parts allowed for weight optimization without sacrificing performance or strength. Weight means a lot in Formula 1. A lighter car is a faster one, though it must also be strong enough not to break apart and designed so that the speed does not send it flying when it makes a turn. Special performance polymers are used to create light, strong parts, while SLA is used to create specially designed light plastic parts. Polypropylene MJF is also a useful technique and SLS and other powder bed techniques are used to print metal parts.

The current goal of 3D printing in Formula 1 is to 3D print automotive parts in a faster design cycle. This allows for even more rapid prototyping. There are also plans for using more different and useful materials as those technologies develop.

At Jawstec, we utilized the same 3D printing tech as is now being used by Formula 1 racing teams. The same principles back much of our design work. The capabilities of 3D printing can be applied to more than just 3D printed auto parts, including drones, computer cases, and much more. Reach out to us today for a CNC quote or to see what our 3D printing design process can do for you and your project!

Really enjoyed this blog. Really looking forward to read more. Really Cool. Zuzana Tobie Jo-Ann